Creating a concrete floor is a vital step in the construction process, and the forms used play a crucial role in its success. Precast forms, made from cast-in-place concrete and pre-cut to specific shapes and sizes, are the most commonly used. These versatile forms offer strength and durability for commercial and industrial applications, as well as cost-effectiveness in terms of labour and materials.

Another option is poured-in-place forms, which are crafted by pouring concrete into previously formed formwork. This method provides greater customization and can be tailored to suit specific needs, but at a higher cost in terms of labour and materials.

When installing concrete floor forms, proper securement and leveling are crucial to ensuring a stable, level floor and preventing gaps between forms. It is also important to regularly check for cracks or signs of settling to maintain structural integrity.

Concrete floor forms, whether precast or poured-in-place, offer a sturdy foundation for further materials and can be customized to suit specific needs.

Their ease of installation and cost-effectiveness make them an essential choice for any construction project. With proper care, they ensure that your concrete floor remains level and robust for years to come.

Concrete Floor Forms

How to form and pour a concrete slab

How to Pour a Concrete Slab (DIY) Family Handyman

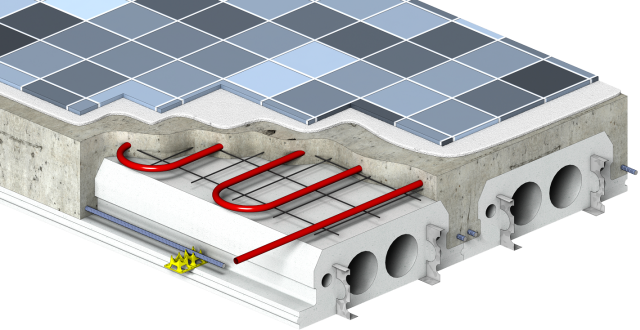

Amdeck: Insulated Concrete Floor and Roof System Amvic

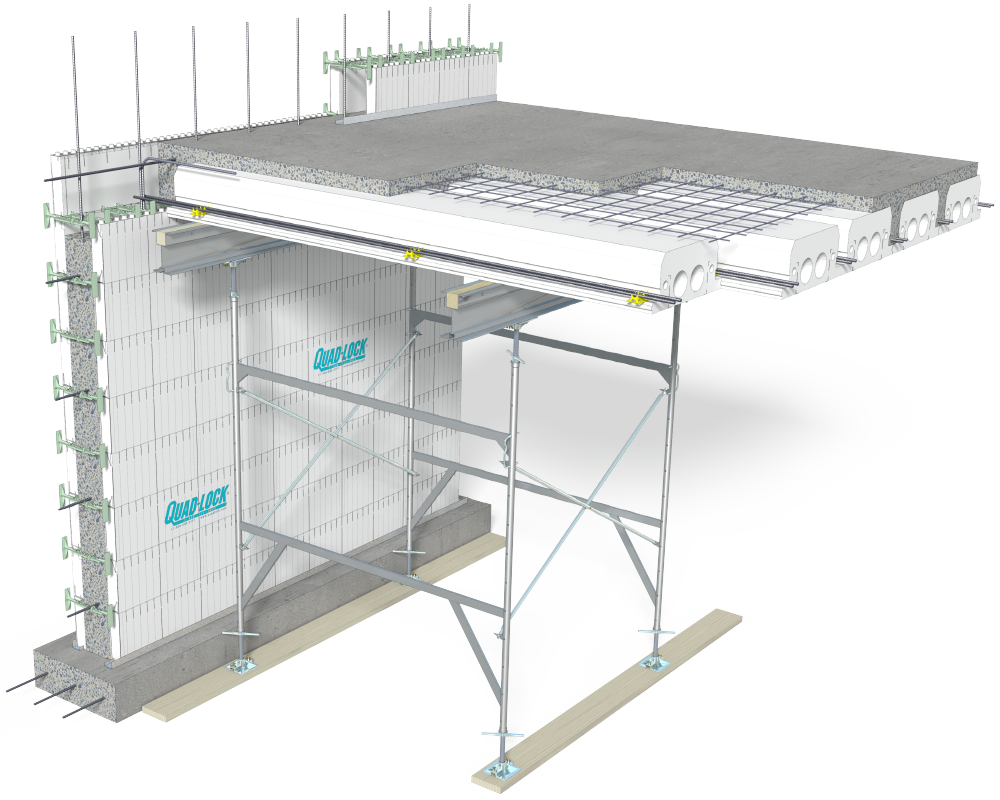

Concrete Roofs and Floors with Quad-Deck Insulated Forms

Removable Forms (Cast-In Place)

Concrete Deck Forms – The EPS-Deck Forming System

Concrete Roofs and Floors with Quad-Deck Insulated Forms

Concrete Deck Forming Systems, EPS-Deck, the Better EPS Deck Forms

Concrete Roofs and Floors with Quad-Deck Insulated Forms

Concrete Forms and Forming – Concrete Network

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floor Epoxy Crack Filler

- Concrete Floor Basement Ideas

- Painting Concrete Floor With Epoxy

- Outdoor Concrete Floor Paint Ideas

- Concrete Floor Painting Tips

- Outdoor Concrete Floor Finishes

- Non Slip Concrete Floor

- Concrete Floor Epoxy Coating

- Outdoor Concrete Floor Tiles