Concrete Floor Sealer Epoxy

Seal-Krete Epoxy Seal Armor Gray 921 5 gal. Concrete and Garage Floor Paint-921005 – The Home Depot

Seal-Krete Clear-Seal Concrete Protective Sealer 1-Part Clear Gloss Garage Floor Epoxy (Actual

Rust-Oleum EpoxyShield 1 gal. Clear Penetrating Concrete Sealer (Case of 2)-265021 – The Home Depot

Rust-oleum 5220 Epoxy Shield Clear Sealer – 5ltr 5220.5 Cromwell Tools

Best Epoxy Concrete Sealer – Your Guide for Using Epoxy Sealants

Epoxy Floor Sealer Clear – Clsa Flooring Guide

Amazon.com: epoxy concrete sealer

Best Epoxy Concrete Sealer – Your Guide for Using Epoxy Sealants

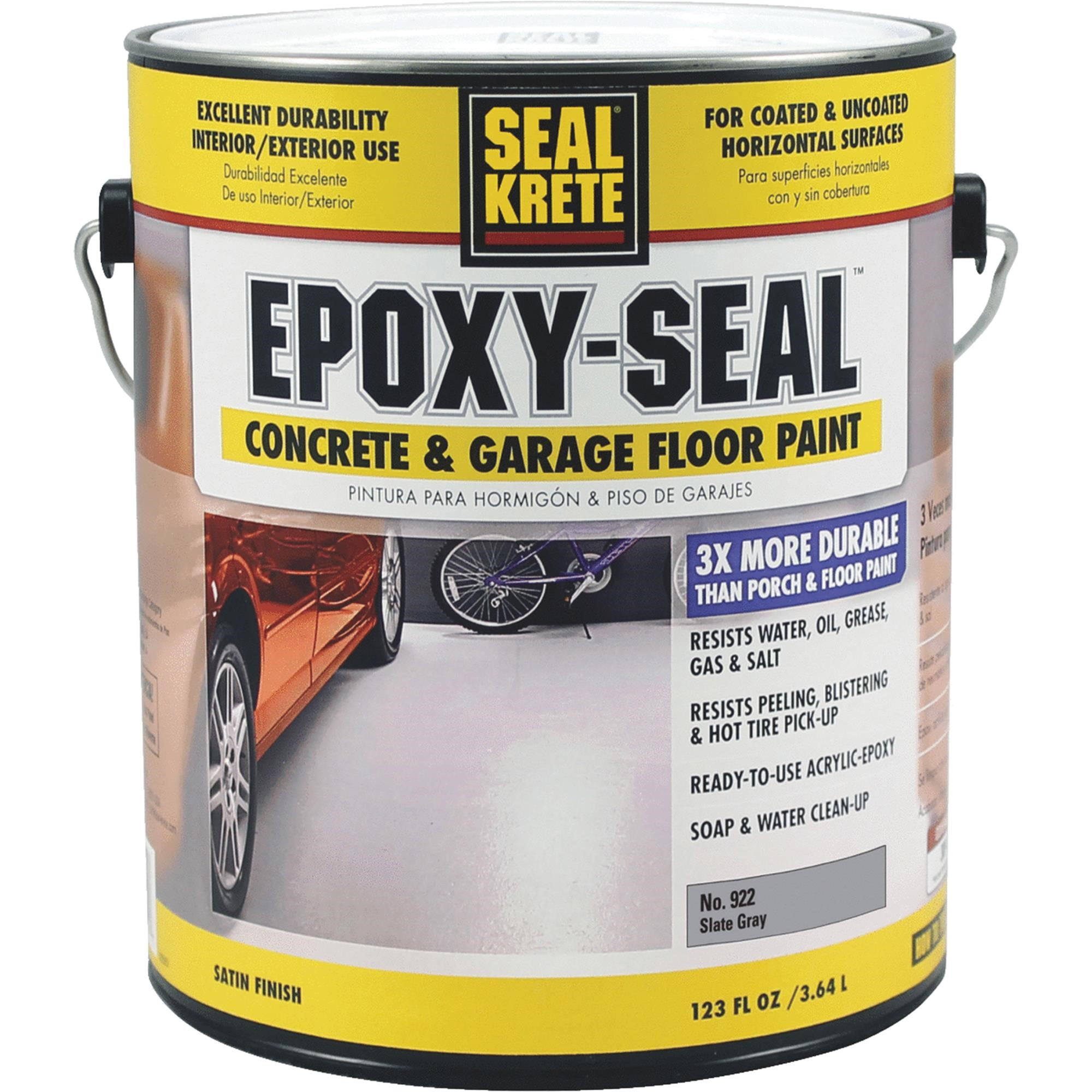

Rust-Oleum Seal-Krete Epoxy-Seal Concrete & Garage Floor Paint, 922 Slate Gray, 1 Gallon

Concrete Countertop Epoxy Sealer Direct Colors

Seal-Krete Lock-Down 1 gal. Epoxy Bonding Floor Primer-106001 – The Home Depot Painted

Related Posts:

- Interior Concrete Floor Paint Ideas

- Concrete Floor Epoxy Crack Filler

- Concrete Floor Basement Ideas

- Painting Concrete Floor With Epoxy

- Outdoor Concrete Floor Paint Ideas

- Concrete Floor Painting Tips

- Outdoor Concrete Floor Finishes

- Non Slip Concrete Floor

- Concrete Floor Epoxy Coating

- Outdoor Concrete Floor Tiles

Concrete floor sealers are an essential component of any construction project, providing a durable and cost-effective protective layer for a variety of surfaces. In particular, concrete floor sealer epoxy is the most popular choice for creating a durable and protective surface on concrete surfaces. This article will discuss the benefits of using epoxy for concrete floors, as well as the different types and methods available for applying it.

## What is Concrete Floor Sealer Epoxy?

Concrete floor sealer epoxy is a type of polymer coating specifically designed to create a moisture-resistant surface on concrete floors. It is one of the most effective methods of protecting concrete surfaces from wear and tear and moisture damage. It also provides a non-slip surface that is ideal for a variety of work and living spaces. The epoxy coating is applied in a two-part mix which then hardens to form a tough waterproof outer layer. Unlike other types of floor sealers, epoxy offers superior physical protection as well as superior chemical resistance.

## Benefits of Using Epoxy for Concrete Floors

The primary benefit of using concrete floor sealer epoxy is its superior lifespan and durability. Thanks to its hard-wearing properties, epoxy can provide up to 15 years of protection on concrete floors without needing to be reapplied. In addition, epoxy offers excellent chemical resistance and is highly resistant to damage caused by fuel and oil spills, making it the perfect choice for industrial settings. Furthermore, when compared to alternatives such as latex paint or asphalt sealers, epoxy offers superior physical protection as well as lasting colour retention. Lastly, epoxy can be used as part of an aesthetically pleasing finish thanks to its range of colours available.

## Types of Epoxy Floor Sealers

When it comes to selecting the best type of epoxy floor sealer, there are several factors to consider such as curing time, application method, coverage area, and compatibility with other materials. The most common types of epoxy floor sealers include water-based coatings, solvent-based coatings, and aliphatic urethane. Each type has its own benefits depending on the intended use. For instance, water-based coatings are quick drying and offer excellent coverage but may not adhere well in areas with high foot traffic. Solvent-based coatings provide better adhesion but have more odour and take longer to apply. Lastly, aliphatic urethane offers maximum protection but requires longer curing times than other types of epoxies.

## Methods for Applying Concrete Floor Sealer Epoxy

Once you’ve selected the best epoxy floor sealer for your needs, it’s time to discuss the different methods for applying it. Typically, two common application methods are used: troweling or brushing/rolling. Troweling is ideal if you want to achieve a smooth high-gloss finish that provides good water resistance while brushing or rolling works best with thin coatings that require good adhesion such as solvent-based coatings. For best results, it’s always recommended to read product instructions carefully before starting your project so that you know exactly what you need to do in order to get the best results from your sealer.

## Conclusion

Concrete floor sealer epoxy is a great way to provide lasting protection against wear and tear and moisture damage for a variety of surfaces. Not only does it offer superior durability compared to conventional latex paint or asphalt sealers but also excellent chemical resistance in industrial settings. With a range of different types and application methods available, there’s no doubt that epoxy is one of the best ways to protect your floors from liquid spills and wear over time. With proper installation and regular maintenance, your floor can be protected with epoxy for up to fifteen years – now that’s value for money!

What are the benefits of a concrete floor sealer epoxy?

1. Durability: Concrete floor sealer epoxy will protect the concrete from damage caused by impacts, abrasion, and chemical exposure. The layer of epoxy resin creates an impermeable barrier which prevents moisture from seeping into the concrete and causing deterioration.2. Aesthetic Appeal: With a glossy finish, concrete floor sealer epoxy can make any concrete floor look newer and more attractive. It also increases the overall durability of the floor, protecting it from staining and wear and tear over time.

3. Easy to Clean: With a sealed epoxy floor, cleaning is much easier as dirt and dust will not penetrate the sealant layer. This is especially useful in commercial spaces, as it helps reduce the amount of time and effort spent on regular cleaning.

4. Non-Slip Surface: When applied to a concrete surface, concrete floor sealer epoxy creates a non-slip surface which reduces the risk of slips and falls. This makes it ideal for areas that are exposed to water or other liquids, such as bathrooms, kitchens, and restaurants.

By selecting the right type of epoxy floor sealer for your needs, you can be sure to get the most out of your investment. With proper installation and maintenance, the benefits of concrete floor sealer epoxy can last for years.

What are the drawbacks of using a concrete floor sealer epoxy?

1. Concrete floor sealer epoxy may have a strong odor that can linger for days or even weeks after application.2. Epoxy floor sealers often require regular maintenance and reapplication to maintain their effectiveness and protective qualities over time.

3. If not applied correctly or in the right environment, the concrete sealer can peel or chip away.

4. There is a risk of delamination if the substrate is not properly prepared before the epoxy is applied.

5. Epoxy coatings are susceptible to staining from oil and other liquids, so spills must be cleaned up quickly to prevent damage.

6. It can be expensive to install, depending on the size of the area that needs to be sealed.

In conclusion, although there are some drawbacks to using a concrete floor sealer epoxy, the benefits far outweigh them. The protection and durability that it provides is unparalleled, making it an excellent choice for any home or commercial space. As long as it is applied correctly and with regular maintenance, the floor sealer epoxy can last for years and ensure that your concrete floors are fully protected.

What are the best ways to apply a concrete floor sealer epoxy?

1. Prepare the surface: Clean the concrete floor thoroughly, removing all dirt, oil, grease and dust. Use a pressure washer or a stiff brush to remove any existing sealers.2. Repair any cracks or imperfections: Use an epoxy repair kit to fill in cracks, holes or other imperfections on the concrete floor.

3. Tape off the edges: To ensure the sealer is applied evenly and does not drip onto surrounding surfaces, tape off the edges of the floor with painter’s tape.

4. Apply the epoxy sealer: Pour a small amount of sealer onto the concrete floor and spread it out with a roller or brush, making sure to cover the entire area. Allow the first coat to dry completely before applying a second coat.

5. Allow time for curing: Epoxy takes up to 24 hours to cure fully, so make sure you give it plenty of time before walking on it or using it in any way.