Designing the flooring of your garage can transform the space from a simple utility area into an aesthetically pleasing and functional extension of your home. With a multitude of options available, choosing the right design can be both exciting and overwhelming. Below are various garage flooring design ideas, exploring their features, benefits, and considerations to help you make an informed decision.

Epoxy Coatings: Durable and Versatile

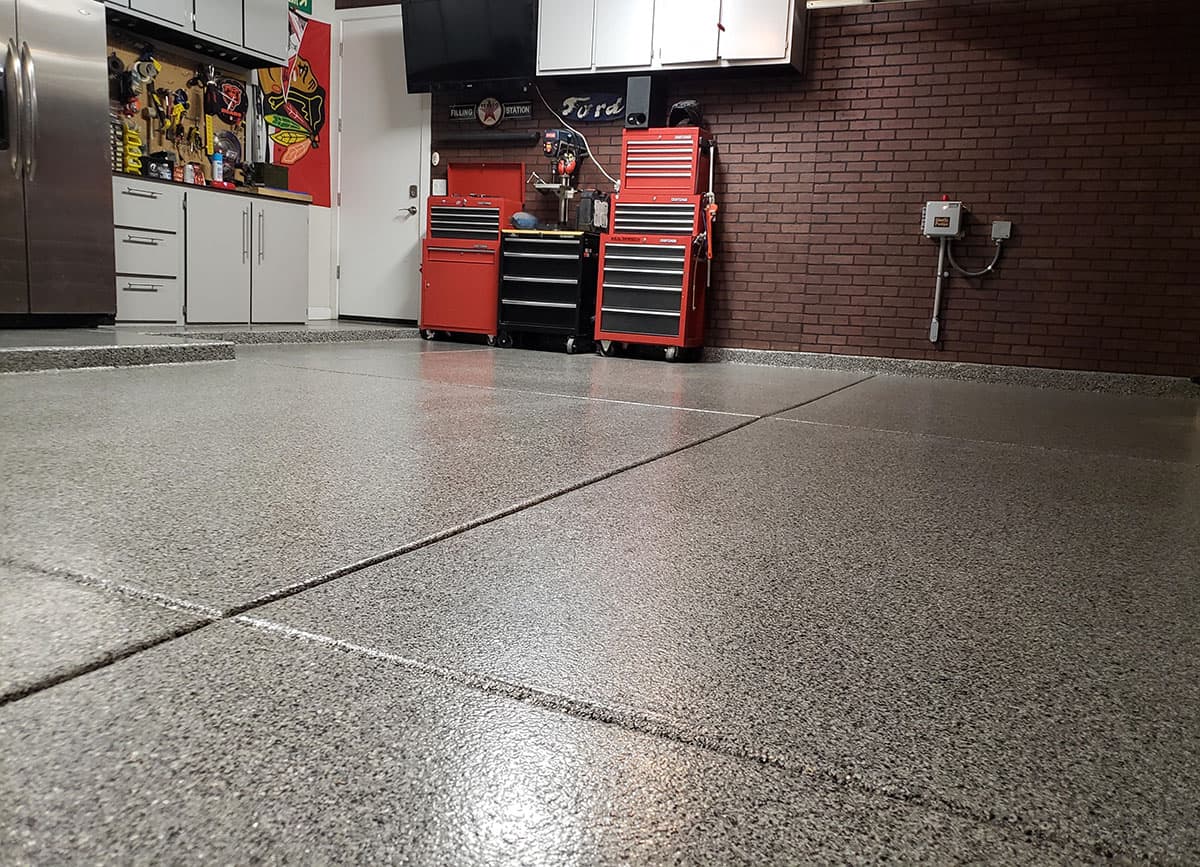

- Introduction to Epoxy Coatings: Epoxy coatings are one of the most popular choices for garage flooring due to their durability and versatility. Composed of a mixture of resin and hardener, epoxy forms a rigid plastic material that bonds exceptionally well to the concrete substrate of your garage floor. This creates a seamless, high-gloss finish that is not only visually appealing but also resistant to wear and tear.

- Benefits of Epoxy Flooring: Epoxy coatings offer several advantages. They are resistant to chemicals, stains, and spills, making them easy to clean and maintain. The high-gloss finish reflects light, brightening up the garage space. Epoxy flooring is also available in various colors and patterns, allowing you to customize the look to suit your taste. Additionally, the durability of epoxy means it can withstand the weight of vehicles and heavy equipment without cracking or peeling.

- Installation Process: The installation of epoxy flooring involves several steps, including surface preparation, mixing the epoxy resin and hardener, application, and curing. Proper surface preparation is crucial for the epoxy to adhere correctly. This often involves cleaning, etching, and patching any cracks or imperfections in the concrete. Once the surface is ready, the epoxy mixture is applied using rollers or squeegees. The floor then needs time to cure, typically 24 to 72 hours, depending on the product and environmental conditions.

- Design Options: One of the major attractions of epoxy flooring is the wide range of design options available. You can choose from solid colors, metallic finishes, and even custom designs such as logos or geometric patterns. Epoxy flakes or chips can be added to the coating to create a textured, non-slip surface. The ability to mix and match colors and finishes allows you to create a unique look that complements the overall design of your home.

- Maintenance and Longevity: Maintaining epoxy flooring is relatively straightforward. Regular sweeping or vacuuming will remove dirt and debris, while occasional mopping with a mild detergent can keep the surface looking clean and shiny. Avoid using abrasive cleaners or tools that could scratch the epoxy. With proper care, epoxy flooring can last for many years, providing a long-term solution for your garage flooring needs.

- Cost Considerations: While epoxy flooring can be more expensive upfront compared to other options, its durability and low maintenance requirements make it a cost-effective choice in the long run. The total cost will depend on factors such as the size of the garage, the type of epoxy used, and whether you choose to hire a professional for installation. DIY kits are available for those who are handy and want to save on labor costs.

Interlocking Tiles: Easy and Customizable

Introduction to Interlocking Tiles

Interlocking tiles are another popular option for garage flooring, known for their ease of installation and customization. These tiles are typically made from durable materials such as PVC or rubber and are designed to snap together without the need for adhesives. This makes them a great choice for DIY enthusiasts looking to upgrade their garage flooring quickly and easily.

Benefits of Interlocking Tiles

The primary advantage of interlocking tiles is their ease of installation. They can be laid directly over existing concrete, even if it has cracks or imperfections. The tiles provide a cushioned surface that is comfortable to stand on and reduces fatigue, making them ideal for workshops or home gyms. Additionally, interlocking tiles are resistant to chemicals, oils, and stains, making them easy to clean and maintain.

Installation Process

Installing interlocking tiles is a straightforward process that requires minimal tools. Start by thoroughly cleaning the garage floor to remove any dirt and debris. Begin laying the tiles in one corner of the garage, snapping them together as you go. Trim any tiles that need to fit around edges or obstacles using a utility knife. Because there are no adhesives involved, the tiles can be easily removed or replaced if needed.

Design Options

Interlocking tiles come in a wide range of colors, patterns, and textures, allowing for endless design possibilities. You can create a checkerboard pattern, use different colors to designate specific areas, or even incorporate logos or custom designs. Some tiles have a diamond plate texture for added grip, while others have a smooth or coin-top surface. The ability to mix and match tiles gives you the freedom to create a unique look for your garage.

Maintenance and Longevity

Maintaining interlocking tiles is simple. Regular sweeping or vacuuming will keep the surface free of dirt and debris. Spills can be wiped up easily, and most tiles can be mopped with a mild detergent. The tiles are designed to withstand heavy loads and resist wear and tear, making them a durable option for garage flooring. However, the lifespan of the tiles can vary depending on the material and the level of traffic and usage.

Cost Considerations

Interlocking tiles are generally more affordable than epoxy flooring and offer a good balance between cost and functionality. The total cost will depend on the type of tiles chosen and the size of the garage. While professional installation is not necessary, purchasing higher-quality tiles can increase the overall cost. Nonetheless, the ease of installation and the ability to customize the design make interlocking tiles a cost-effective and attractive option for many homeowners.

Polished Concrete: Sleek and Modern

Introduction to Polished Concrete

Polished concrete is a sleek and modern option for garage flooring that has gained popularity in recent years. This process involves grinding and polishing the existing concrete surface to achieve a smooth, glossy finish. Polished concrete is not only visually appealing but also incredibly durable and low maintenance, making it an excellent choice for those looking to enhance the look of their garage.

Benefits of Polished Concrete

Polished concrete offers several benefits, including its durability and longevity. The polishing process strengthens the concrete, making it resistant to wear and tear, stains, and moisture. The high-gloss finish reflects light, brightening up the garage space and creating a clean, modern look. Additionally, polished concrete is easy to clean and maintain, requiring only regular sweeping and occasional mopping.

Installation Process

The installation of polished concrete involves multiple steps, starting with the preparation of the existing concrete surface. This may include cleaning, patching, and grinding to remove any imperfections. The concrete is then polished using progressively finer grinding tools until the desired level of shine is achieved. A sealer or densifier may be applied to enhance the finish and protect the surface. The entire process can take several days to complete, depending on the condition of the concrete and the size of the garage.

Design Options

While polished concrete is often associated with a sleek, industrial look, there are various design options available to customize the appearance. You can choose from different levels of sheen, from a matte finish to a high-gloss mirror-like surface. Concrete stains or dyes can be used to add color and create unique patterns or designs. Additionally, decorative saw cuts or scoring can be incorporated to create geometric patterns or borders.

Maintenance and Longevity

Maintaining polished concrete is straightforward and involves regular sweeping or vacuuming to remove dirt and debris. Occasional mopping with a pH-neutral cleaner will keep the surface looking clean and shiny. Polished concrete is highly durable and can last for many years with minimal maintenance. The application of a sealer every few years can help protect the surface and maintain its appearance.

Cost Considerations

The cost of polished concrete can vary depending on factors such as the condition of the existing concrete, the level of polish desired, and the size of the garage. While polished concrete can be more expensive than some other flooring options, its durability and low maintenance requirements make it a cost-effective choice in the long run. Hiring a professional is recommended for the best results, as the polishing process requires specialized equipment and expertise.

Roll-Out Vinyl Flooring: Quick and Practical

Introduction to Roll-Out Vinyl Flooring

Roll-out vinyl flooring is a practical and cost-effective option for those looking to upgrade their garage floor quickly. This type of flooring comes in large rolls that can be easily unrolled and cut to fit the dimensions of your garage. Vinyl flooring is durable, resistant to stains and moisture, and provides a comfortable surface to walk on.

Benefits of Roll-Out Vinyl Flooring

The primary advantage of roll-out vinyl flooring is its ease of installation. Unlike other flooring options that require extensive preparation and multiple steps, vinyl flooring can be installed in a matter of hours. It is also resistant to chemicals, oils, and stains, making it easy to clean and maintain. Additionally, vinyl flooring provides a cushioned surface that is comfortable to stand on, reducing fatigue during long hours of work in the garage.

Installation Process

Installing roll-out vinyl flooring is a straightforward process. Start by thoroughly cleaning the garage floor to remove any dirt and debris. Unroll the vinyl and allow it to acclimate to the temperature of the garage for a few hours. Cut the vinyl to fit the dimensions of the garage, making sure to leave a small gap around the edges for expansion. Secure the vinyl to the floor using double-sided tape or adhesive, if necessary. The entire process can be completed in a single day, making it a quick and convenient option.

Design Options

Roll-out vinyl flooring is available in a variety of colors and patterns, allowing you to customize the look of your garage. You can choose from solid colors, textured patterns, or even designs that mimic the appearance of tile or stone. The ability to mix and match different rolls of vinyl gives you the freedom to create a unique design that suits your taste and complements the overall aesthetic of your home.

Maintenance and Longevity

Maintaining vinyl flooring is simple and requires only regular sweeping or vacuuming to remove dirt and debris. Spills can be wiped up easily, and the surface can be mopped with a mild detergent. While vinyl flooring is durable and resistant to wear and tear, it is not as long-lasting as some other options. Over time, heavy traffic and exposure to UV rays can cause the vinyl to fade or wear down. However, with proper care, vinyl flooring can provide a practical and attractive solution for your garage for several years.

Cost Considerations

Roll-out vinyl flooring is one of the most affordable options for garage flooring. The cost will depend on the quality of the vinyl and the size of the garage. While professional installation is not necessary, opting for higher-quality vinyl can increase the overall cost. Nonetheless, the ease of installation and low maintenance requirements make vinyl flooring a cost-effective choice for many homeowners.

Rubber Flooring: Safe and Comfortable

Introduction to Rubber Flooring

Rubber flooring is a safe and comfortable option for garage flooring, particularly for those who use their garage as a workshop or home gym. Made from recycled rubber tires, this type of flooring is durable, shock-absorbent, and slip-resistant. Rubber flooring provides a cushioned surface that reduces fatigue and minimizes the risk of injury, making it an excellent choice for high-traffic areas.

Benefits of Rubber Flooring

The primary advantage of rubber flooring is its safety and comfort. The cushioned surface provides excellent shock absorption, reducing the impact on joints and minimizing the risk of injury. Rubber flooring is also slip-resistant, even when wet, making it a safe choice for areas prone to spills. Additionally, rubber flooring is resistant to chemicals, oils, and stains, making it easy to clean and maintain.

Installation Process

Installing rubber flooring is relatively simple and can be done using interlocking tiles or roll-out mats. Start by thoroughly cleaning the garage floor to remove any dirt and debris. If using interlocking tiles, begin laying them in one corner of the garage, snapping them together as you go. If using roll-out mats, unroll the mats and cut them to fit the dimensions of the garage. Secure the tiles or mats to the floor using adhesive, if necessary. The entire process can be completed in a single day, making it a quick and convenient option.

Design Options

Rubber flooring is available in a variety of colors, patterns, and textures, allowing you to customize the look of your garage. You can choose from solid colors, speckled patterns, or even designs that mimic the appearance of tile or stone. The ability to mix and match different tiles or mats gives you the freedom to create a unique design that suits your taste and complements the overall aesthetic of your home.

Maintenance and Longevity

Maintaining rubber flooring is simple and requires only regular sweeping or vacuuming to remove dirt and debris. Spills can be wiped up easily, and the surface can be mopped with a mild detergent. Rubber flooring is highly durable and can withstand heavy traffic and exposure to the elements, making it a long-lasting option for garage flooring. With proper care, rubber flooring can provide a safe and comfortable solution for your garage for many years.

Cost Considerations

Rubber flooring is generally more expensive than some other options, but its safety and comfort features make it a worthwhile investment. The cost will depend on the type of rubber flooring chosen and the size of the garage. While professional installation is not necessary, opting for higher-quality rubber can increase the overall cost. Nonetheless, the durability and low maintenance requirements of rubber flooring make it a cost-effective choice for many homeowners.

Stained Concrete: Stylish and Unique

Introduction to Stained Concrete

Stained concrete is a stylish and unique option for garage flooring that allows you to customize the appearance of your concrete surface. This process involves applying a stain to the concrete to create a range of colors and effects, from subtle earth tones to vibrant hues. Stained concrete is durable, low maintenance, and can add a distinctive look to your garage.

Benefits of Stained Concrete

Stained concrete offers several benefits, including its durability and longevity. The staining process penetrates the surface of the concrete, creating a permanent color that will not fade, chip, or peel. Stained concrete is also resistant to moisture, stains, and wear and tear, making it an excellent choice for high-traffic areas. Additionally, stained concrete is easy to clean and maintain, requiring only regular sweeping and occasional mopping.

Installation Process

The installation of stained concrete involves several steps, starting with the preparation of the existing concrete surface. This may include cleaning, patching, and etching to remove any imperfections and open the pores of the concrete. The stain is then applied using a sprayer, roller, or brush, and allowed to penetrate the surface. Once the desired color is achieved, a sealer is applied to protect the surface and enhance the finish. The entire process can take several days to complete, depending on the condition of the concrete and the size of the garage.

Design Options

Stained concrete offers a wide range of design options, allowing you to customize the appearance of your garage floor. You can choose from different types of stains, including acid-based stains that create a mottled, variegated effect, and water-based stains that offer a more uniform color. Additionally, stains can be combined with decorative saw cuts or scoring to create unique patterns or borders. The ability to mix and match colors and effects gives you the freedom to create a distinctive look that complements the overall design of your home.

Maintenance and Longevity

Maintaining stained concrete is straightforward and involves regular sweeping or vacuuming to remove dirt and debris. Occasional mopping with a pH-neutral cleaner will keep the surface looking clean and vibrant. The application of a sealer every few years can help protect the surface and maintain its appearance. Stained concrete is highly durable and can last for many years with minimal maintenance, providing a long-term solution for your garage flooring needs.

Cost Considerations

The cost of stained concrete can vary depending on factors such as the condition of the existing concrete, the type of stain used, and the size of the garage. While stained concrete can be more expensive than some other options, its durability and low maintenance requirements make it a cost-effective choice in the long run. Hiring a professional is recommended for the best results, as the staining process requires specialized equipment and expertise.

Common Mistakes to Avoid

Inadequate Surface Preparation

One of the most common mistakes in garage flooring installation is inadequate surface preparation. Failing to properly clean and prepare the surface can lead to adhesion issues and a shorter lifespan for the flooring. Ensure that the surface is free of contaminants and has the appropriate texture for the flooring material to bond effectively.

Incorrect Mixing Ratios

Incorrect mixing ratios of materials such as epoxy resin and hardener can result in improper curing and compromised performance. Always follow the manufacturer’s instructions carefully and use the appropriate tools to ensure thorough mixing. Inaccurate mixing can lead to issues such as bubbling, peeling, or an uneven finish.

Skipping Ventilation

Skipping proper ventilation during installation can expose installers to harmful fumes and affect indoor air quality. Ensure adequate ventilation by using fans, opening windows, and wearing respirators if necessary. Proper ventilation helps dissipate VOCs and protects both installers and building occupants from potential health risks.

Insufficient Curing Time

Allowing insufficient curing time can compromise the durability and performance of the flooring. Avoid walking on or placing objects on the floor until it is fully cured. Follow the manufacturer’s guidelines for curing time to ensure that the flooring achieves its full strength and durability.

Ignoring Temperature and Humidity Conditions

Ignoring temperature and humidity conditions during installation can lead to issues such as improper curing, bubbling, or cracking. Follow the manufacturer’s guidelines for optimal temperature and humidity conditions. Controlling these environmental factors is crucial for the successful installation and long-term performance of the flooring.

Failing to Conduct Post-Installation Inspections

Failing to conduct post-installation inspections can result in undetected defects or issues that may worsen over time. After the flooring has cured, perform a thorough inspection to identify any areas with uneven thickness, bubbles, or inadequate adhesion. Addressing these issues promptly can prevent further problems and ensure the longevity of the flooring.

What is the best garage flooring option for heavy-duty use?

For heavy-duty use, epoxy flooring is often considered the best option due to its exceptional durability and resistance to chemicals, stains, and wear and tear. It can withstand the weight of vehicles and heavy equipment without cracking or peeling, making it ideal for high-traffic areas and demanding environments.

How do I maintain my garage floor to ensure longevity?

Maintaining your garage floor involves regular cleaning to remove dirt and debris, as well as prompt attention to spills to prevent stains. For epoxy, rubber, and vinyl floors, mopping with a mild detergent is recommended. For polished and stained concrete, using a pH-neutral cleaner is advisable. Periodically applying a sealer can also help protect the surface and maintain its appearance.

Can I install garage flooring myself, or should I hire a professional?

Many garage flooring options, such as interlocking tiles, roll-out vinyl, and rubber mats, can be installed as DIY projects. However, options like epoxy coatings, polished concrete, and stained concrete require specialized equipment and expertise for proper installation. Hiring a professional for these types of flooring can ensure a high-quality finish and long-lasting performance.

Are there eco-friendly garage flooring options available?

Yes, there are eco-friendly garage flooring options available, such as rubber flooring made from recycled tires and low-VOC (volatile organic compound) epoxy coatings. These options minimize environmental impact while providing durable and attractive flooring solutions. When selecting eco-friendly flooring, look for certifications and product information that highlight their sustainable attributes.

How do I choose the right design for my garage floor?

Choosing the right design for your garage floor involves considering factors such as the intended use of the space, your aesthetic preferences, and your budget. For a sleek and modern look, polished concrete or stained concrete can be ideal. For a more customizable and colorful option, interlocking tiles or epoxy coatings offer a wide range of design possibilities. Consider the overall design of your home and how the garage floor can complement it.

What are the cost implications of different garage flooring options?

The cost of garage flooring options varies widely based on the material, installation complexity, and garage size. Epoxy coatings and polished concrete tend to be on the higher end of the cost spectrum but offer long-term durability and low maintenance. Interlocking tiles, roll-out vinyl, and rubber flooring are generally more affordable and easier to install. When evaluating cost, consider both the upfront investment and the long-term maintenance and durability of the flooring.

Related Posts: