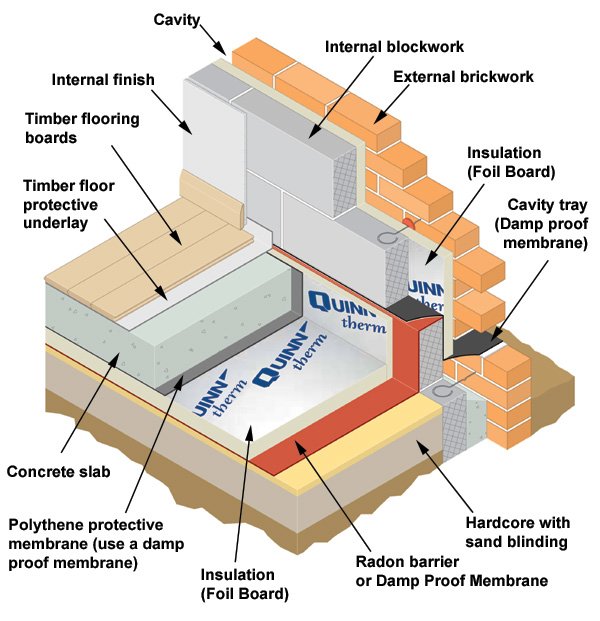

An insulated concrete floor slab detail involves a concrete slab integrated with a layer of rigid insulation, enhancing energy efficiency and comfort. This setup prevents heat loss, providing thermal resistance and reducing energy bills. Ideal for both residential and commercial buildings, it ensures a stable indoor climate. The insulation layer also acts as a moisture barrier, contributing to a durable, long-lasting foundation that supports a comfortable living environment.

Insulated Concrete Floor Slab Detail

E5SMEW25 Concrete Ground Bearing Floor, Insulation below Slab LABC

E5MCFF26 Concrete Ground Bearing Floor, Insulation Below Slab LABC

Insulating A Concrete Floor Slab – Flooring Guide by Cinvex

Insulating slab-on-ground floors BRANZ Build

E5MCFF30 Suspended In-Situ Concrete Floor, Insulation Below Slab LABC

E5SMEW1 Suspended Beam and Block Floor, Insulation Slab LABC

Slab Edge Insulation: Why it Matters ProTradeCraft

E5MCPF24 Concrete Ground Bearing Floor, Insulation Below Slab LABC

http://basc.pnnl.gov/sites/default/files/images/TE%204-2%20Slab%20independent%20of%20foundation

E5MCPF28 Suspended In-Situ Concrete Floor, Insulation Below Slab LABC

Related Posts:

- Concrete Floor Grinding Pads

- Concrete Floor Clear Coat

- Quikrete Basement Concrete Floor Paint

- Concrete Floor Cleaning Tips

- Fixing Timber Battens To Concrete Floor

- How To Raise Concrete Floor

- Kilz Concrete Floor Sealer

- Concrete Floor Finishes Photos

- Concrete Floor Radiant Heating

- Concrete Floor Patch Epoxy

Insulated Concrete Floor Slab Detail: A Comprehensive Guide

Insulated concrete floor slabs are a popular choice for many residential and commercial buildings today. They provide a strong and durable foundation that is capable of withstanding heavy loads, while also providing a thermally-insulated space, making them an ideal choice for all sorts of structures.

In this guide, we’ll take a look at the detail behind insulated concrete floor slabs, including the different types of insulation, the installation process and the benefits of using this type of flooring.

### Types of Insulation for Insulated Concrete Floors

When it comes to insulating concrete floors, there are two main types to consider: rigid foam insulation and loose fill insulation.

Rigid foam insulation is usually made from expanded polystyrene (EPS) or extruded polystyrene (XPS) materials and is installed directly onto the concrete slab. It insulates the slab by forming an airtight layer between the floor and the concrete. This type of insulation is typically more expensive than loose fill insulation, but it offers better thermal performance.

Loose fill insulation is a less expensive option, typically made from cellulose or fiberglass materials. It is poured over the top of the slab and then tamped down to a level surface. This type of insulation provides less thermal performance than rigid foam insulation and can be more prone to settling over time.

### Installing an Insulated Concrete Floor Slab

Installing an insulated concrete floor slab requires careful preparation and planning in order to ensure that it is properly installed. Here are some key steps to follow:

1. Layout and measure the area where the slab will be placed, taking note of any obstructions or potential hazards that may need to be addressed.

2. Excavate the area to desired depth and shape, then level the base using a laser level or other form-finding tool.

3. Place the reinforcing steel in position and secure it to the ground using rebar ties or other fasteners as necessary.

4. Pour the concrete mix into the area, using a concrete mixer if available, and tamp it evenly with a tamping tool.

5. Allow the concrete to cure for at least 24 hours before beginning installation of insulation materials.

6. Install rigid foam or loose fill insulation as desired based on performance requirements and budget constraints.

7. Install any additional features such as vapor barriers or drainage systems as required by local building codes or project requirements.

8. Allow the entire assembly to cure for at least 48 hours before walking on or using the floor surface.

### Benefits of Installing an Insulated Concrete Floor Slab

Insulated concrete floor slabs offer numerous benefits over traditional slab construction methods such as improved thermal performance, increased structural stability, and enhanced fire resistance capabilities. They also provide superior sound deadening properties compared to other types of flooring, making them ideal for sound sensitive applications such as recording studios or medical facilities. Additionally, they are highly resistant to changes in temperature or moisture levels which makes them suitable for a wide range of climates and environments.

In addition to these benefits, insulated concrete floors also provide superior energy efficiency when compared to traditional foundations, helping reduce energy costs throughout their lifespan while also reducing carbon emissions associated with heating and cooling operations in commercial buildings. They also require minimal maintenance once installed, saving property owners time and money over time while also increasing their overall property value due to their enhanced durability and longevity when compared to other types of flooring systems.

Overall, insulated concrete floor slabs are an excellent choice for anyone looking for a strong yet insulated foundation solution that can withstand heavy loads while providing superior thermal performance and sound reduction capabilities in any environment.