Wood Floor Underlay Soundproof

Best Soundproof Underlayment of 2022: All Floor Types! – Snoring Source

Cerazorb® Acoustic Underlayment For Multiple Flooring Types – Sound Seal

Soundproof Flooring Underlay for Sale Soundproof Cow Flooring underlayment, Sound proofing

Serena Mat® Underlay – Soundproof your Floor with tested results.

Comfort Gold 5mm – Acoustic Underlay For Wood or Laminate Flooring – Any Size eBay

ProBase® Rubber Underlayment For Engineered Hardwood & Laminate Flooring – Sound Seal

Serena Mat® Underlay – Soundproof your Floor with tested results.

How To Soundproof A Wooden Floor : SPC Solution 3 – Soundproof Floor Assembly Soundproofing

Hardwood Floor Acoustic Underlayment – Carpet Vidalondon

Timbertech2 Acoustic Plus Flooring Underlay – Acoustic membrane

Soundproof a floor: Standard (Level 2) Soundproofing Company

Related Posts:

- How To Install Pergo Wood Flooring

- Dark Black Wood Flooring

- Solid Wood Flooring White

- Pallet Wood Flooring Ideas

- Wood Floor Chevron Pattern

- Wood Flooring Home Ideas

- Wood Floor Filler Resin

- Glossy Wood Flooring Ideas

- Pergo Wood Flooring Installation

- Wood Floor Interior Design

Wood floor underlay is becoming increasingly popular as a method of reducing noise in the home or office. The material is designed to absorb sound, reduce echo, and cancel vibrations, leading to a quieter, more peaceful environment. But how do you know which type of wood floor underlay is best for your needs? This article will go over the different types of underlay available and provide tips on ensuring you get the most beneficial noise reduction from your wood floor underlay.

What is Wood Floor Underlay?

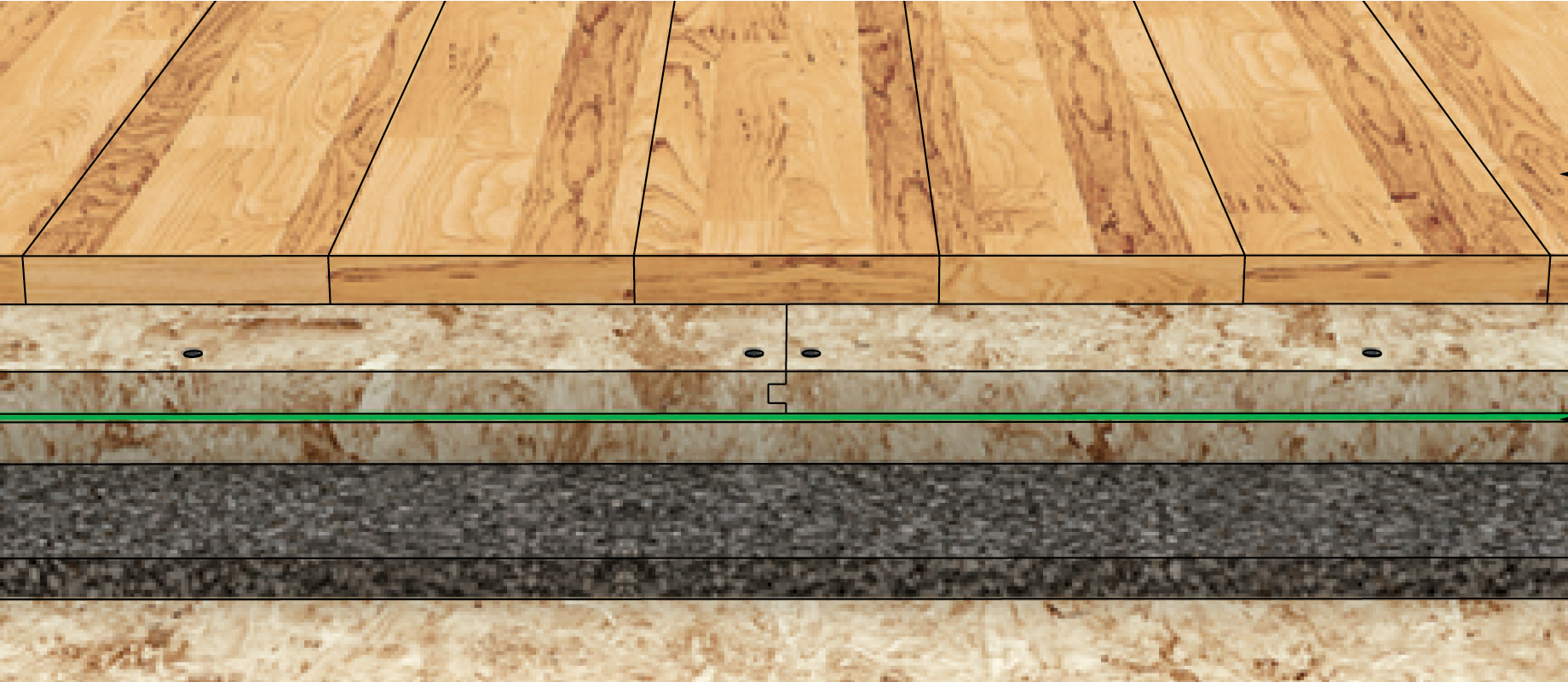

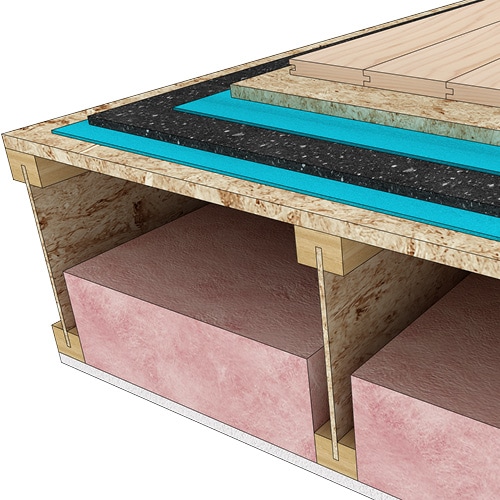

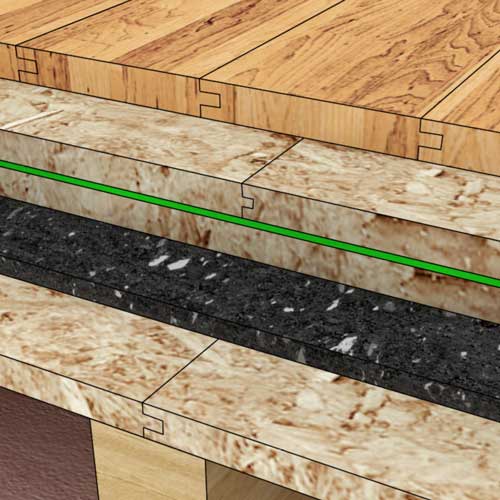

Wood floor underlay is typically made up of either foam or rubber material and is placed between a wood subfloor and the finished wood flooring. It is designed to act as a cushioning layer between the two surfaces while muffling any sound that would otherwise escape from the room. The underlay also helps to protect the wood flooring, preventing it from cracking due to movement in the subfloor underneath it.

Types of Wood Floor Underlay

There are a number of different types of wood floor underlay available, each offering varying levels of noise reduction. Foam and rubber are the most popular choices, but there are also recycled wood fibre and cork options. Each type has its own advantages and disadvantages, so it’s important to do your research to find out which one provides the most effective noise reduction.

Foam Underlay

Foam wood floor underlay is generally made up of polyethylene foam and is most commonly used in residential settings. It has an excellent ability to absorb sound, reducing noise levels by up to 15 decibels in some cases. Foam underlay also offers superior insulation, helping to keep rooms warm in colder months.

Rubber Underlay

Rubber wood floor underlay is often used in commercial settings due to its superior soundproofing abilities. It has an extremely high noise performance rating, absorbing up to 28 decibels of sound depending on its thickness. Rubber underlay also offers superior insulation, making it an ideal choice for reducing noise in busy areas such as offices or restaurants.

Recycled Wood Fibre Underlay

Recycled wood fibre underlay is made from offcuts or sawdust from carpentry workshops and furniture manufacturers. The material traps air within its fibres, providing excellent insulation while also helping to absorb sound waves and reduce echo. It’s generally more affordable than other types of wood floor underlay and can be used with heated floors if necessary.

Cork Underlay

Cork underlay is gaining popularity due to its natural soundproofing abilities and eco-friendly credentials. It’s made up high-density cork particles that helps reduce vibration as well as sound levels. Cork is also naturally fire-resistant, making it a great choice for areas where there’s a risk of fire such as kitchens or living rooms.

Tips for Maximizing Noise Reduction with Wood Floor Underlay

Choose the Right Type

The first step in getting the most beneficial noise reduction from your wood floor underlay is choosing the right type for your needs. Consider factors such as where the underlay will be used (commercial or residential), whether there’s a risk of fire (cork may be a better choice), and how much noise reduction you need (foam and rubber are better for higher levels).

Install Properly

Another key factor in getting maximum soundproofing benefits from your wood floor underlay is installing it correctly. Make sure that all seams between sections are sealed with tape or caulk and that all gaps between the walls and ceilings are filled with acoustic foam insulation. This will help ensure your room stays quiet even when exposed to loud noises from outside sources such as traffic or construction work.

Invest in Quality Products

Finally, it’s important to invest in quality products when choosing your wood floor underlay. Lower quality materials may not be able to provide the same level of noise reduction as top-of-the-line products, making them less beneficial when it comes to reducing noise levels in your home or office. Look for products that come with quality warranties or guarantees to ensure you’re getting the most out of your investment.

Conclusion

Wood floor underlay can be an effective way to reduce noise levels in any space. However, It’s important to consider factors such as type, installation, and quality when purchasing your underlay to make sure you’re getting the best possible solution. With these tips, you can be sure you’re investing in a product that will provide the noise reduction you need.

What type of underlayment is best for soundproofing wood floors?

The best type of underlayment for soundproofing wood floors is a high-density rubberized acoustic mat or an insulation-grade foam. These materials provide excellent soundproofing. Rubberized mats are usually thicker and denser than foam and provide greater insulation. They also have the advantage of being more moisture-resistant. Foam underlayment can be easily installed by cutting it to fit the shape of the room. It is also lightweight and inexpensive, making it a great choice for soundproofing wood floors.What other options are there besides underlayment for soundproofing wood floors?

1. Mass Loaded Vinyl: Mass Loaded Vinyl (MLV) is a heavy, flexible material that can be used as a soundproofing barrier for both wood and concrete floors. It works by blocking and absorbing noise, rather than reflecting it back into a room.2. Acoustic Carpet Underlayment: Acoustic carpet underlayment is specifically designed to reduce noise. It works by creating a cushion between the flooring and the subfloor, trapping any sound waves and absorbing them before they can escape into the room.

3. Rubber Pads or Sheets: Using rubber pads or sheets underneath your wood floor can help reduce noise. The rubber helps to dampen sound by absorbing it, rather than reflecting it back into the room.

4. Soundproof Paint or Sealant: Soundproof paint or sealant can be applied directly to the surface of your wood floor, creating a soundproof barrier between the floor and the subfloor. This will help to reduce the amount of noise that is transmitted through the flooring.

What are the pros and cons of using underlayment for soundproofing wood floors?

Pros:-Underlayment helps soundproof wood floors by absorbing sound waves and reducing the amount of sound travelling through the floor.

-It also helps to protect the wood floor from moisture, wear and tear, and temperature changes.

-It is relatively inexpensive and easy to install.

Cons:

-It can add thickness to the floor, which may be noticeable in some circumstances.

-It may reduce the “bounce” or feeling of solidity in the floor.

-It can reduce the efficiency of subfloor heating systems.