Concrete Floor Epoxy Repair

Quikrete 862049 Multi-Purpose Epoxy Concrete Repair, 8.6 Oz – toolboxsupply.com

When to call a professional to repair cracked concrete

Quikrete 0.5 lb. 8.6 oz. Epoxy Concrete Repair-862049 – The Home Depot

Rizistal Epoxy Resin Concrete Repair Mortar 10 Colours

Rizistal Epoxy Resin Concrete Repair Mortar 10 Colours

DIY Epoxy Concrete Crack Repair – What I use – How I Repair Concrete

Garage floor epoxy Epoxy service Las Vegas & Henderson, NV

Epoxy Floor Repair Products – Flooring Ideas

Rizistal Deep Fill Epoxy Concrete Repair Mortar Cold Cure

Rizistal Epoxy Concrete Repair Mortar Fast Cure 10 Colours

Epoxypatch, 100% Solids Epoxy Concrete Floor & Crack Repair

Related Posts:

- Concrete Floor Tile Installation

- Stained Concrete Floor Tiles

- Concrete Floor Tiles

- Concrete Floor Coating Systems

- Concrete Floor Paint Color Chart

- Concrete Floor Rubber Coating

- Concrete Floor Tile Preparation

- Basement Concrete Floor Coatings

- Heavy Duty Concrete Floor Cleaner

- Durall Concrete Floor Coatings

Having a concrete floor with an epoxy coating is great for industrial and commercial settings. But with time and heavy use, these concrete floors will start to show signs of wear and tear. To keep your epoxy coated floor looking good and functioning properly, you must take care of it properly. In this article, we will go over some tips on how to maintain and repair your epoxy coated concrete floor.

## Understanding the Basics of Epoxy Coated Concrete Floors

Epoxy coating is a form of protective coating which helps protect the surface of the concrete floor from environmental degradation, such as water damage, chemicals, oil, and other debris. It also acts as a decorative layer and can help create the desired look for the space.

The epoxy coating is applied in two components: a base coat which is made up of a polyurethane resin, and a seal coat which is made up of silicone resin or other synthetic compounds. This multi-layer approach helps create an adherent film that bonds to the concrete surface.

## Maintaining Your Epoxy Coated Concrete Floors

One of the best ways to ensure that your epoxy coated floor continues to look great is to clean it regularly. Using soft-bristle brushes or damp mops can help remove any dirt and debris that has collected on the floor. In addition, it’s important to never use any abrasive cleaning products or tools as they can scratch or damage the epoxy coating.

It’s also a good idea to inspect your floor once every few months for any cracking or lifting in the floor’s coating. If you do happen to find any areas that have begun to crack or lift, you should take immediate action in order to prevent further damage from taking place.

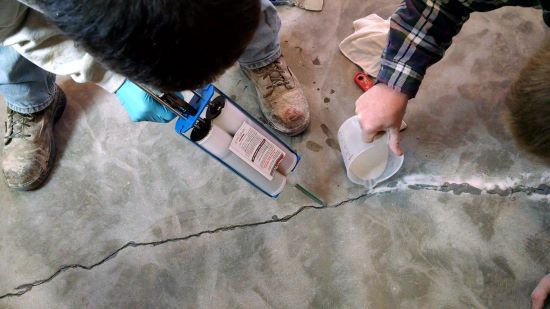

## Repairing Your Epoxy Coated Concrete Floors

If you do find areas of your epoxy coated floor that have cracked or lifted, repairs must be made quickly in order to protect the underlying concrete from further damage. The repair process begins by scrubbing away any broken pieces of epoxy coating around the area before filling the area with a paste-like material designed specifically for repairing epoxy coated concrete floors. Once the paste has cured (which typically takes around 5 hours) you should apply at least one new layer of sealant/protective topcoat onto the area in order to ensure that it is properly sealed off from the environment.

In some cases, extremely large cracks may require more extensive repairs which may include removing old layers of epoxy coating and applying new layers in their place. In such cases, it’s best to consult with a professional who can evaluate the situation and provide you with advice on how best to proceed with repairs.

## Conclusion

If you have a concrete floor with an epoxy coating, it’s important that it is cared for properly in order to ensure its long-term performance. This includes regular cleaning using soft-bristle brushes or damp mops as well as timely inspections for any cracking or lifting of the epoxy coating. If any repairs need to be made, you can take action right away using paste-like materials designed specifically for repairing epoxy coated concrete floors. And if necessary, you can also consult with a professional who can provide advice on how best to proceed with repairs on larger cracks and damages.

What type of epoxy is best for repairing a concrete floor?

The type of epoxy used to repair a concrete floor will depend on the specifics of the situation, such as the severity and location of the damage. In general, a self-leveling epoxy is usually considered to be the best option for repairing a concrete floor. This type of epoxy is designed to fill in cracks and other voids, as well as to create an attractive finish. It is also highly durable and resistant to scratches, stains, and moisture.What is the best way to prepare a concrete floor for epoxy repair?

The best way to prepare a concrete floor for epoxy repair is to clean, etch, and vacuum the floor. Begin by thoroughly cleaning the concrete with a pressure washer and/or degreaser to remove any dirt, grease, or debris. Then, use an etching solution or a light sandblasting to create a rough surface that will give the epoxy coating an area to adhere to. Finally, vacuum the area to remove any dust or loose particles. At this point, the concrete should be ready for epoxy application.What tools are needed to prepare a concrete floor for epoxy repair?

1. Vacuum2. Broom

3. Concrete grinders and polishers

4. Angle grinder

5. Edge chisel and hammer

6. Paint scraper

7. Paintbrush

8. Cleaning detergents/cleaners

9. Measuring tape

10. Painter’s tape

11. Protective eyewear and gloves

12. Masking tape

13. Epoxy repair kits

What type of surface preparation is required for epoxy repair on a concrete floor?

The best surface preparation method for epoxy repair on a concrete floor is to diamond grind the affected area to remove any damaged material and create a clean, even surface. It is also important to patch any cracks or holes if necessary, followed by grinding again once the patches have dried. Finally, the surface should be vacuumed and neutralized to ensure proper adhesion of the epoxy.What are the steps to properly prepare a concrete floor for epoxy repair?

1. Clean the floor: Thoroughly clean the floor with a broom and vacuum. Make sure to remove any dirt, dust, or debris from the surface.2. Repair any damage: If there are any cracks or chips in the concrete, repair them with a concrete patch or filler.

3. Sand the floor: Use a sander to level out any uneven surfaces or to smooth down any ridges on the floor.

4. Test the surface:In order to determine if the concrete is porous enough for an epoxy coating, test a small area with water. If it absorbs quickly, you will need to apply a primer coat before applying the epoxy.

5. Prepare for epoxy application: Remove any oil or grease from the surface by using a degreaser or Detergent and water solution. Rinse thoroughly and allow the area to dry completely before applying epoxy.