Tools Required For Laminate Flooring

Tools Needed For Laying Laminate Flooring – Dulux Living Room

Wood Flooring Tools / Professional Flooring Jack Install Hard Wood Straight Tile Contractor Hand

Laminate Flooring Installation Tools Needed – LAMINATE FLOORING

Laminate Flooring Installation Tools Needed – LAMINATE FLOORING

Wood & Laminate Flooring Cutters – Roberts Consolidated

Wood Flooring Laminate Installation Floor Fitting Kit Set Tool Wooden DIY Home eBay

Laminate Flooring Tools Needed / DIY Project: Replace Vinyl Flooring with Laminate : Install and

How To Cut Laminate Flooring Without Power Tool / Floating laminate flooring comes apart as easy

Tools Needed to Install Laminate Flooring Find The Home Pros

Tools Needed To Install Laminate Flooring – Flooring : Home Design Ideas #qVP2Vob2Pr91220

Tools Needed To Install Hardwood Floor

Related Posts:

- Laminate Flooring For Steps

- Wood Laminate Flooring In Kitchen

- Laminate Floor Glue Removal

- Natural Oak Laminate Flooring

- Wood Laminate Flooring Colors

- Laminate Floor Around Doors

- Silver Grey Oak Laminate Flooring

- DIY Laying Laminate Flooring

- Wood Laminate Flooring Care

- Laminate Flooring Wood Planks

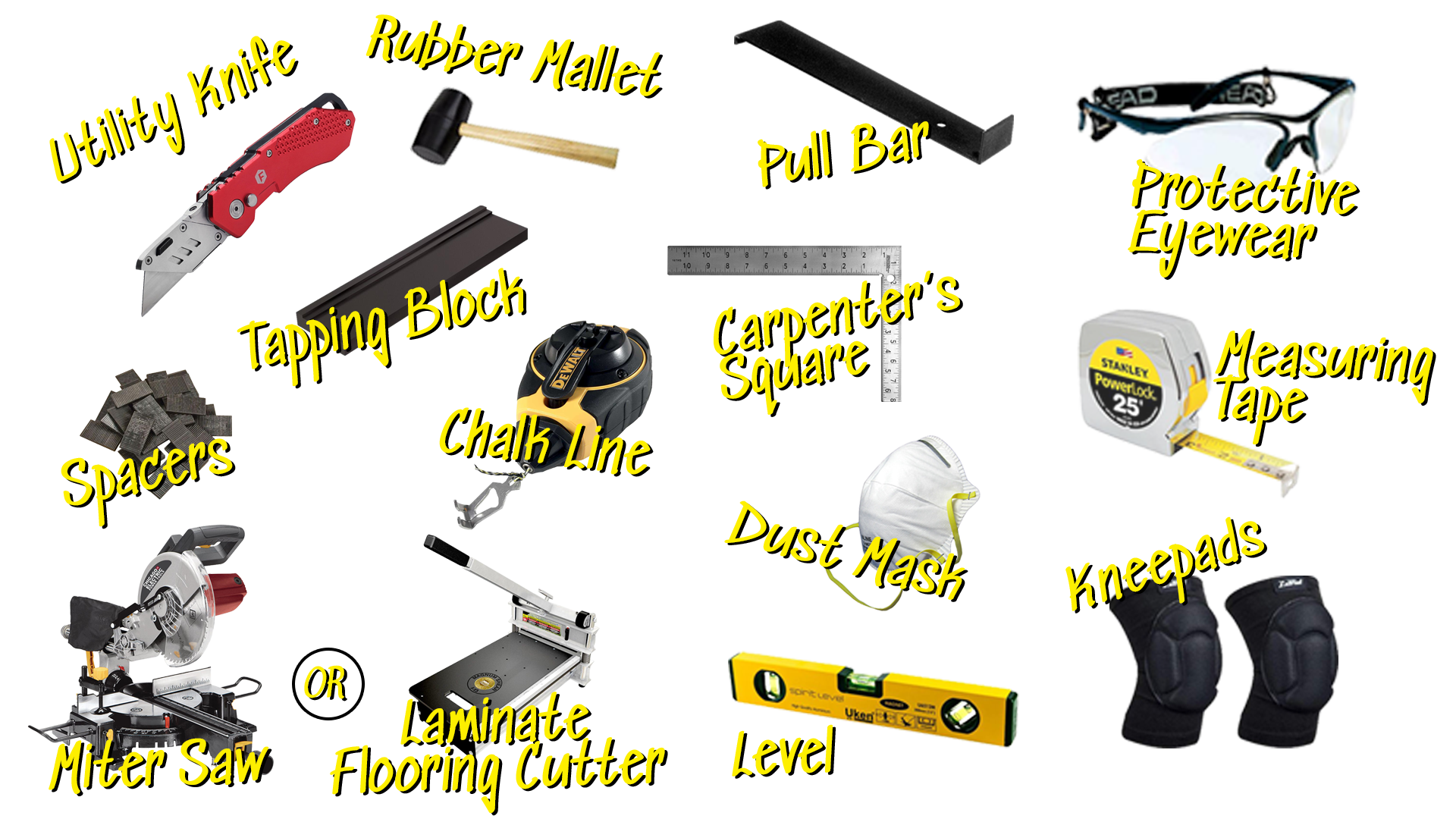

Installing a laminate floor is a time-consuming task that requires plenty of patience and preparation. To complete the job successfully, it’s important to have all the right tools ready for use. From cutting boards and saws to measuring tapes and glue, these are the essential tools required for laminate flooring projects.

## Measuring Tape and Pencil

The first step in any major DIY project is to measure the room correctly, and this is especially true for installing a laminate floor. A tape measure is essential for determining the length and width of the space, as well as measuring any obstacles such as furniture or appliances. A pencil and paper are also needed to record exact measurements so that you can ensure accurate cuts when you begin laying down the planks.

## Hammer and Nail Set

Once you have completed measuring and cutting the laminate flooring planks, you’ll need to hammer them together. This requires a hammer with enough force to secure the nails, as well as a nail set that can be used to counter sink the nails. Having several sizes handy helps ensure that all pieces fit together snugly, no matter their size or shape.

## Saw and Cutting Board

Precise measurements are essential when cutting laminate planks for doorways, corners, and other tricky areas. To do this properly, you will need a saw with a blade specifically designed for cutting laminate floors. It’s also important to invest in a good-quality cutting board in order to ensure accurate cuts.

## Spacers and Glue

After nailing down the planks, it’s important to make sure the spacing between them remains consistent in order to maintain an even look throughout the entire room. The best way to do this is by using plastic spacers that are placed between the planks when they are secured together. Some types of laminate flooring will also require glue along the sides of each plank in order to keep them securely connected.

## Mallet

When installing laminate flooring, it’s inevitable that some of the planks won’t fit together snugly or require extra force to connect them properly. In these situations, it’s better to use a mallet instead of a hammer in order to avoid damaging either the surface or back of the planks. The mallet should be made from rubber or plastic so that it won’t leave too many marks on your newly installed floor.

Laminate flooring might seem like an intimidating task at first glance, but having all the right tools can make your job a lot easier. With preparation and preparation correctly, your DIY project will be finished in no time!

What is the best underlayment for laminate flooring?

Most experts recommend using a foam underlayment specifically designed for laminate flooring. These types of underlayments are usually made of polyethylene foam and feature a moisture barrier to protect against water damage. They also provide extra cushioning and sound insulation, making them ideal for rooms with heavy foot traffic.What type of material is best for underlayment?

The best type of material for underlayment depends on the specific application. For flooring projects, foam or cork are commonly used due to their shock-absorbing properties. For roofing applications, a synthetic underlayment is usually preferred due to its resistance to water damage. In some cases, a combination of materials may be used, such as a layer of foam topped with a layer of rubberized asphalt for added protection.What is the difference between underlayment and subfloor?

Underlayment is a layer of material installed directly over the subfloor before the final finish flooring is applied. It provides a smooth, level surface for the finish flooring to lay on and adds insulation and noise reduction properties. Subfloor is a structural layer found directly above a crawl space or concrete slab. It provides support for the underlayment and finished flooring, and is typically made of plywood or oriented strand board.What type of underlayment is best for subfloors?

The best type of underlayment for subfloors is one that provides cushioning and insulation against impact noise and moisture. These types of underlayment include cork, foam, rubber, and felt. Foam underlayment is usually the most popular choice, as it provides both soundproofing and thermal insulation. Additionally, foam underlayment is often the least expensive option.What is the purpose of an underlayment for subfloors?

An underlayment for subfloors is used to provide an extra layer of support and insulation for the flooring material. Underlayment also helps to reduce noise, even out minor imperfections in the subfloor surface, and improve the overall performance of the flooring. It is typically made of materials like foam, cork, or rubberized asphalt, and should be installed in accordance with manufacturer recommendations.What types of underlayment can be used for subfloors?

1. Foam pad with adhesive: A foam pad is an inexpensive and simple solution for many subfloor situations. It can provide cushioning and sound insulation and is often used in conjunction with a plywood or OSB subfloor. The foam comes with an adhesive backing so it can be quickly installed and easily replaced when necessary.2. Cork underlayment: Cork is a great underlayment choice for many applications, providing moisture protection and sound insulation. It can be used as an underlayment for both hardwood and laminate flooring, and is often used in conjunction with an additional layer of plywood or other material.

3. Soundproofing mats: Soundproofing mats are typically made of rubber or vinyl and are designed to absorb sound in order to reduce noise levels in a room. They can also provide a bit of cushioning, making them a suitable choice for use under floating floors.

4. Acoustic underlayment: This type of underlayment is designed specifically to reduce the noise of foot traffic or furniture movement on a floor above it. It is often used in apartments and other multi-story buildings to reduce noise between floors.

What is the difference between underlayment and subfloor?

Underlayment and subfloor are both materials used in flooring installations, however, they are used for different purposes. Underlayment is a thin layer of material, typically plywood, that is installed directly on top of your existing floor and provides a smooth, level surface for the new floor covering. Subfloor is typically thicker than underlayment and is installed directly over the floor joists or beam structure as a base for the finished floor. Subfloor provides structural support for the finished floor and can also help to provide sound insulation.What is the purpose of underlayment and subfloor?

Underlayment is a thin layer of material that is placed between a subfloor and the flooring material, such as carpet, tile, or wood. It provides a smooth and level surface for the flooring to adhere to, as well as a cushioning effect to reduce noise and impact from walking on the floor.The subfloor is the base structural layer of the floor that provides the foundation for all other layers. It is usually made out of plywood and provides stability for the entire floor structure.