Engineered Hardwood Flooring Thickness

Hardwood Flooring Thickness Chart Project PDF Download – Woodworkers Source

Recommended Thickness of Engineered Wood floor – Wood and Beyond Blog

5 Proven Hardwood Flooring Thickness Categories – Easiklip Floors

Which Is Better: Solid Wood or Engineered Wood Flooring Engineered wood floors, Engineered

Vietnamese Engineered Wood Flooring Size Guide – L&C Flooring,Leading Vietnam engineered

American Made Hardwood Flooring – Engineered 3/4 Inch & Solid

engineered hardwood floor thickness – Teena Bedford

Lvp Flooring Vs Engineered Hardwood / Hardwood floors vs. Laminate vs. Luxury Vinyl Plank (LVP

3/4" Inch Thick Engineered Hardwood Flooring – 5.8 mm Wear Layer

Oak Engineered Wood Flooring, Thickness: 15mm, Finish Type: Matte, Rs 200 /square feet ID

Three layer hardwood flooring and two layer middle layer – CADORIN

Related Posts:

- Hardwood Floor Cleaning Tips

- Hardwood Floor Decorating Ideas

- Hardwood Floor In A Kitchen

- Engineered Hardwood Flooring

- Rustic Oak Hardwood Flooring

- Parquet Hardwood Flooring

- Hardwood Floor Duster

- Homemade Hardwood Flooring

- Hardwood Floor Stain Colors

- Hardwood Floor Repair DIY

Engineered hardwood flooring is a popular alternative to traditional hardwood floors that is constructed using multiple layers of pressed wood and topped with a veneer layer of real hardwood. This type of flooring is usually much thicker than traditional hardwood, with the average plank measuring between 5 and 10 millimeters thick. However, there are variations in thickness, which can affect the look, durability, and cost of the flooring.

## Types of Engineered Hardwood Flooring

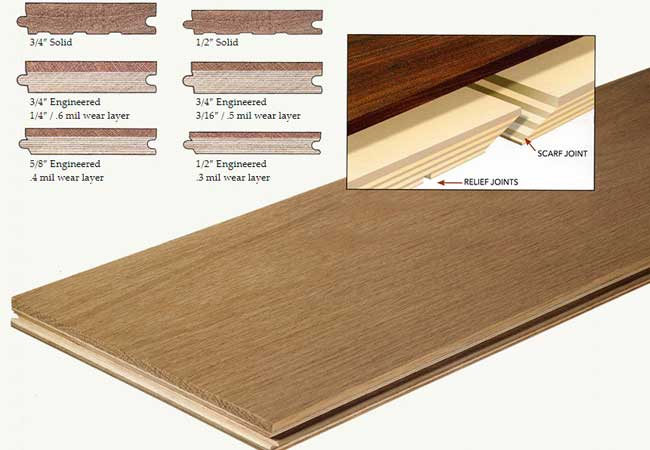

The most common type of engineered hardwood flooring is the multi-layer construction, which typically has three to five layers. The top layer is the wear layer, made from a thin layer of hardwood that provides the finish. The middle layers are composed of multiple layers of pressed wood, such as plywood or particleboard. The bottom layer is a heavy-duty stabilizing layer that keeps the planks from expanding or contracting due to changes in temperature and humidity. The total thickness will depend on the number of layers used.

## Advantages of Thicker Engineered Flooring

Thicker engineered flooring can offer significant advantages over thinner options. One such advantage is increased stability. Since thicker planks offer more layers of cushioning, they can help reduce the risk of wear and tear over time, as well as reduce the risk of warping or buckling due to excessive moisture or temperature fluctuations. Thicker engineered flooring can also provide more sound insulation than thin options, making it ideal for multi-story dwellings or for homeowners who need extra noise reduction.

## Disadvantages of Thicker Engineered Flooring

When considering engineered hardwood flooring thickness, it’s important to keep in mind that thicker planks may come with some drawbacks. One potential issue is that thicker planks may require more subfloor preparation prior to installation, such as leveling and smoothing the surface. Additionally, thicker planks can be more expensive than thinner options due to their increased material costs and increased labor costs associated with installation.

## How Thick Should Your Engineered Floor Be?

The optimal thickness will depend on your individual situation and preferences. If you’re looking for greater stability and sound insulation, a thick plank may be preferable. However, if you’re on a budget or working with an existing subfloor that would need additional work for thicker planks, then a thin option may be the better choice. Regardless of what you choose, it’s important to keep in mind that thicker planks are not necessarily better than thinner ones – it’s all about finding what works best for your space and budget.

What is the standard thickness of engineered hardwood flooring?

The standard thickness of engineered hardwood flooring is 3/8 inch (9.5 mm). However, there are variations in thickness, with some options ranging from 1/4 inch (6.35 mm) to 3/4 inch (19.05 mm).What is the difference between engineered hardwood and solid hardwood flooring?

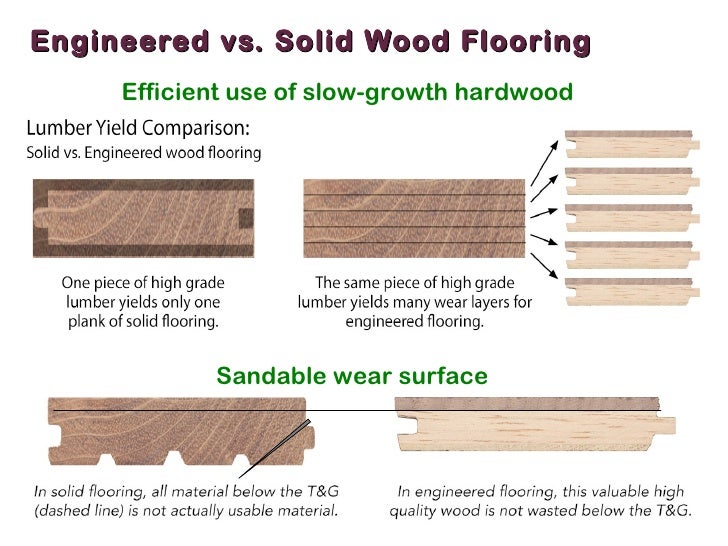

Engineered hardwood flooring is composed of several layers of wood that are laminated together. It typically has a thin veneer of real wood on top, while the rest of the layers are made of plywood or other materials. Engineered hardwood is more stable than solid hardwood and is less likely to expand and contract with changes in humidity and temperature.Solid hardwood flooring is composed of one solid piece of wood throughout, and generally requires more tending to as it is more prone to expansion and contraction than engineered hardwood. It also requires more frequent sanding and refinishing since it will wear down faster than engineered hardwood over time. Solid hardwood also tends to be more expensive than engineered hardwood, however, it adds a natural look and feel that is difficult to replicate with other flooring types.

What is the cost difference between engineered hardwood and solid hardwood flooring?

Engineered hardwood flooring is typically less expensive than solid hardwood flooring. The average cost of engineered hardwood flooring ranges from $3 to $12 per square foot installed, while solid hardwood can range from $5 to $20 per square foot installed.What are the advantages and disadvantages of engineered hardwood flooring compared to solid hardwood flooring?

Advantages of Engineered Hardwood Flooring1. More stable and resistant to warping and expansion due to its layered construction.

2. Easier to install compared to traditional hardwood flooring, since it can be floated or glued down (no nails required).

3. Can be installed at all levels of the home, including above grade and in basements where moisture and humidity may be an issue.

4. Less expensive than solid hardwood flooring.

5. More scratch and dent resistant than solid hardwood flooring due to its thicker wear layer.

Disadvantages of Engineered Hardwood Flooring

1. Not as aesthetically pleasing compared to solid hardwood, depending on the wear layer thickness.

2. Cannot be refinished if the wear layer is too thin.

3. Some wood species are cheaper than others and may lack the character of solid hardwood flooring.

What are the differences between engineered hardwood flooring and solid hardwood flooring?

Engineered hardwood flooring is composed of multiple layers of wood that are bonded together under heat and pressure to create a strong, stable base. Engineered hardwood flooring can be installed over concrete or directly onto subfloors that are above grade and in some cases below grade. It has a top layer of real wood, so it looks like solid hardwood, but because it is more stable and less prone to expansion and contraction due to moisture, it is an ideal choice for basements or other areas with higher levels of humidity.Solid hardwood flooring is a single layer of real wood milled from lumber trees. It is usually available in tongue and groove planks that are nailed or glued to the subfloor. Solid hardwood flooring is very durable, but can be prone to shrinking and expanding due to changes in humidity or temperature. It should generally not be used in areas where there are high levels of moisture, such as in basements or bathrooms.

What are the benefits of engineered hardwood flooring?

1. Durability: Engineered hardwood flooring is incredibly durable due to the multiple layers of construction, which makes it more resistant to dents and scratches.2. Cost: Engineered hardwood flooring can be less expensive than solid wood flooring since it uses less expensive materials in its construction process.

3. Stability: Engineered hardwood flooring is less prone to shifting or warping due to its stabilized core and top layers which means it is an excellent choice for any environment with fluctuating temperatures.

4. Installation: Engineered hardwood flooring can be installed over most subfloor types including concrete, plywood, and even ceramic tile, allowing for a much easier and faster installation process.

5. Aesthetic: Engineered hardwood flooring comes in a variety of styles and finishes that can help lend a unique look to any space.