Concrete Floor Tolerances

Concrete Floor Flatness Tolerance – Carpet Vidalondon

ACI Tolerances for Concrete Construction Concrete Construction Magazine

Floor Flatness And Levelness Chart Two Birds Home

Concrete Floor Tolerances – Flooring Site

Concrete Floor Flatness Tolerance – Carpet Vidalondon

catena consulting engineers blog

Concrete floor flatness tolerances in line with the Concrete Society’s TR34 4th edition 2013

ACI Tolerances for Concrete Construction Concrete Construction Magazine Construction

Concrete Floor Level Tolerances – Flooring Things

Concrete Floor Tolerances – Flooring Site

Related Posts:

- Staining Concrete Floors How To

- Refinishing Old Concrete Floors

- Concrete Floor Faux Finish

- Resurfacing A Concrete Floor

- Concrete Floor Sealer And Paint

- Faux Concrete Floor Tiles

- Insulated Concrete Floor Slab Detail

- Concrete Floor Resurfacing Cost

- Polished Concrete Floors How To

- Concrete Floor Vapor Barrier Installation

Concrete floor tolerances are the specifications that determine the size, shape, and level of flatness that a concrete floor must meet in order to be considered successful. In order to make sure that a concrete floor meets these specifications, a variety of measurements and tests need to be taken. Knowing the exact requirements for a concrete floor is essential for builders, architects, engineers, and contractors to ensure that projects are completed in accordance with regulations.

## What Are Concrete Floor Tolerances?

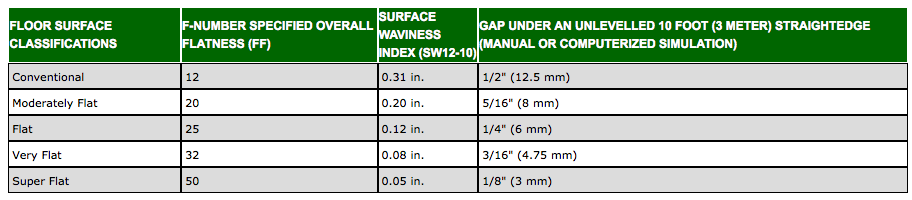

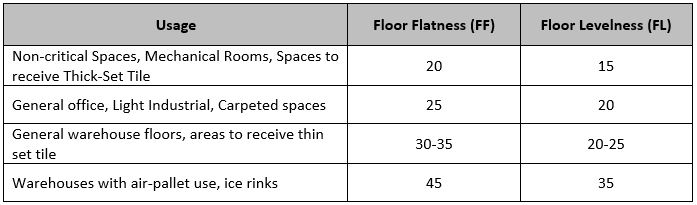

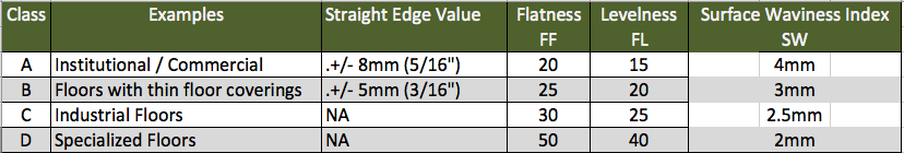

Concrete floor tolerances refer to the maximum deviation from flatness or levelness of a concrete surface. This is usually measured with a special type of laser level, which can measure how close a surface is to being perfectly flat or level. These measurements are necessary to ensure that the surface meets the desired specifications.

The tolerance levels for concrete floors vary depending on its intended use. For example, a concrete floor in an industrial setting would have different requirements than one in a residential space. Generally, the higher the tolerance required, the more precise and expensive the project will be.

## Types of Concrete Floor Tolerances

The types of concrete floor tolerances depend on the use of the floor and the specific requirements of each project. Common types of tolerances include:

* Flatness: This refers to how level a concrete surface is when measured across its width or length.

* Levelness: This refers to how level a concrete surface is when measured across its entire area.

* Permissible Slab Deflection: This refers to how much movement or deflection is allowed in a concrete slab when it is loaded with weight or force.

* Joints: Joints refer to any type of break between two sections of concrete that is used to separate them and absorb any movement in the slab due to shrinkage or expansion caused by temperature changes.

* Step Height: This refers to how far apart two steps can be on a staircase or ramp made out of concrete.

* Crack Control: This refers to how much cracking is allowed in a concrete slab before it needs to be replaced or repaired.

## How Are Concrete Floor Tolerances Measured?

Concrete floor tolerances are typically measured using specialized laser levels. These devices measure the flatness and levelness of a surface with precision accuracy. They can also measure other factors such as permissible slab deflection, step height, joint separation, and crack control.

There are also other methods used to measure concrete floor tolerances such as using templates, strings, straight edges, and measuring tapes. However, these methods are not as accurate as using a laser level since they require manual measurements which can be imprecise and prone to error.

## Factors That Affect Concrete Floor Tolerances

There are several factors that can affect how precise and accurate concrete floor tolerances will be. These include:

* The type of aggregate used in the mixture – The type of aggregate and its size can affect how well the mixture holds together and how flat or level it will be after being poured.

* The mix design – The mix design determines how much water is used in relation to other ingredients such as cement and sand. Too much water can lead to improper curing which can cause cracking and uneven surfaces.

* The amount of finishing – Finishing work such as troweling and power troweling affects how level and smooth the surface will be after it has been poured and set.

* Temperature – Temperature affects how quickly the mixture sets which can lead to cracking if it sets too quickly or unevenly. It can also cause warping if it sets too slowly or unevenly due to temperature differences between parts of the slab.

## Conclusion

Concrete floor tolerances are essential in making sure that all projects are completed according to regulations and specifications set by building codes and other authorities. Knowing what types of tolerances are needed, as well as how they should be measured and what factors affect them, is important for anyone involved in construction work involving concrete floors. Accurate measurements are essential for making sure that projects meet safety standards while also looking good aesthetically speaking.