Epoxy Floor Cove Base

cove-base Massachusetts Epoxy Flooring Contractor

A Contractor Trick for Applying Epoxy Cove Base – Plexi-Chemie, Inc.

A Contractor Trick for Applying Epoxy Cove Base – Plexi-Chemie, Inc.

Epoxy Base Cove Installation Seamless Floorging

Integral Epoxy Cove Base – Vintage Resurfacing

Epoxy/Urethane, Metallic, Resinous, Polyaspartic Flooring System

Epoxy cove base flooring system contractor – FDA, USDA regulations

Epoxy Superior Polymer Products

epoxy cove base – Google Search Epoxy floor, Cove base, Baseboards

Troweled Integral Cove Base Epoxy Floor Base

A Contractor Trick for Applying Epoxy Cove Base – Plexi-Chemie, Inc.

Related Posts:

- Concrete Floor Epoxy Colors

- Clear Epoxy Wood Floor Finish

- Advantages Of Epoxy Flooring

- Crazy Epoxy Floor

- Epoxy Paint Floor Garage

- How To Apply Flakes To Epoxy Floor

- Epoxy Laminate Flooring

- Epoxy Resin Garage Floor Paint

- Designer Epoxy Floor Paint

- Industrial Garage Floor Epoxy

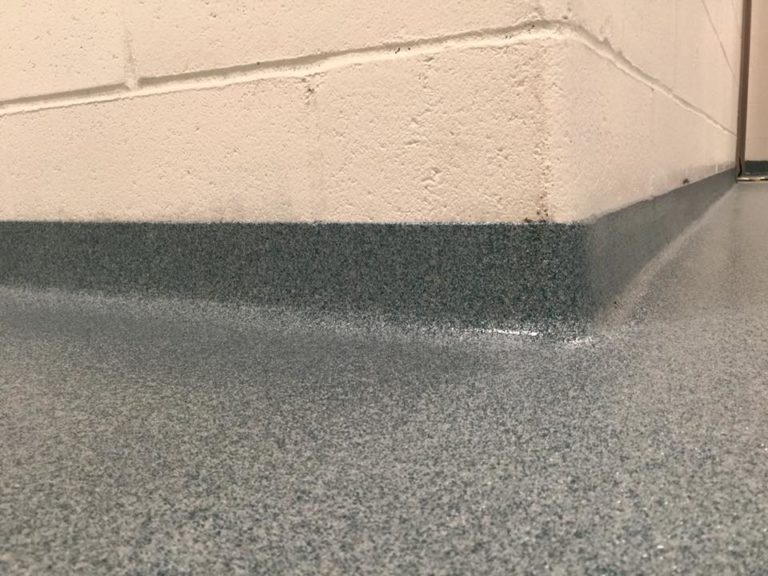

When it comes to flooring options for commercial spaces, epoxy floor cove base is an increasingly popular choice. Epoxy flooring is a durable, cost-effective solution that can be applied to both new and existing floors and walls. It is used in a variety of settings, including hospitals, schools, warehouses, factories, retail stores, office buildings, and more.

The advantages of epoxy floor cove base include its resistance to impact, chemicals, and temperature changes. It is also easy to clean and maintain, even in high-traffic areas. With its non-slip surface, epoxy floor cove base is a safe option for any commercial space. Additionally, it can be installed quickly and with minimal disruption to the area.

Epoxy floor cove base is typically made from two components: resin and a hardener. The resin is mixed with the hardener before being applied to the surface in either a liquid or powder form. Depending on the type of epoxy coating used, it can be applied in multiple layers for extra protection or as a single layer for an economical solution.

Once the epoxy has been applied to the surface, it must be cured in order to set and harden. The curing process occurs over several days and involves exposing the epoxy to heat or UV light. Curing helps ensure that the epoxy bonds properly to the surface and creates a strong, durable coating that will last for years.

The cost of installing epoxy floor cove base depends on several factors including the size of the area, the type of epoxy used, and the complexity of the job. However, when compared to other types of flooring such as carpet or tile, epoxy is typically more affordable. Additionally, due to its durability and easy maintenance requirements, it often pays for itself over time through reduced repair and replacement costs.

If you’re looking for a practical and affordable solution for your commercial space, epoxy floor cove base may be an ideal option. With its resistance to chemicals, impact damage, and temperature changes coupled with its ease of installation and maintenance, it can provide long-term value for any setting.