ESD Epoxy Flooring Specifications

Esd Epoxy Flooring Specifications – Flooring Guide by Cinvex

Esd Epoxy Flooring Specifications – Flooring Guide by Cinvex

Ace Star Industries Sdn Bhd – ESD Epoxy Floor Coating

ESD Paint / ESD Epoxy Flooring ESD Flooring Clean Room Construction Philippines, Asia Pacific

Esd Epoxy Flooring Specifications – Flooring Ideas

ESD Epoxy Flooring, इएसडी फ्लोरिंग in Sulur, Coimbatore , G Care Inc. ID: 18965894362

ESD EPOXY FLOORING at Rs 150/square feet Epoxy Flooring ID: 22300704188

ESD EPOXY FLOORING at Rs 150/square feet Epoxy Flooring ID: 22300704188

323 Sqft Epoxy ESD Flooring, Delhi, Rs 105/sq ft Aroindia Electromech Private Limited ID

Epoxy ESD Flooring Service, For Home,Hospital, Lorven Solutions ID: 22447898288

Static Dissipative Epoxy Flooring – Flooring Ideas

Related Posts:

- Concrete Floor Epoxy Colors

- Clear Epoxy Wood Floor Finish

- Advantages Of Epoxy Flooring

- Crazy Epoxy Floor

- Epoxy Paint Floor Garage

- How To Apply Flakes To Epoxy Floor

- Epoxy Laminate Flooring

- Epoxy Resin Garage Floor Paint

- Designer Epoxy Floor Paint

- Industrial Garage Floor Epoxy

If you’re an engineer or a facility manager in a high-tech industry, you know that ESD epoxy flooring is essential to protect sensitive electrical components and machinery. But what exactly are the specifications of ESD epoxy flooring? In this article, we’ll look at an overview of the different types of ESD epoxy flooring and their associated specifications.

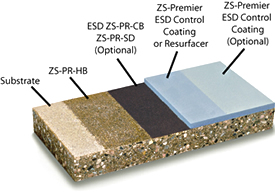

## Types of ESD Epoxy Flooring

There are two main types of ESD epoxy flooring: Conductive and Static Dissipative. Conductive epoxy flooring is used in highly sensitive areas such as cleanrooms, microelectronics, and semiconductor manufacturing. This type of epoxy flooring typically has a surface electrical resistance of 1 x 10⁻¹⁰ ohms or lower. Static dissipative epoxy flooring is used in less sensitive areas such as computer rooms, warehouses, and laboratories. This type of epoxy flooring typically has a surface electrical resistance between 1 x 10⁻¹⁰ ohms and 1 x 10⁹ ohms.

## ESD Epoxy Flooring Standards

The IEC 61340-5-1 standard is the most widely accepted standard for ESD epoxy flooring. It sets out the requirements for selecting, installing, testing, monitoring, and maintaining ESD epoxy flooring in order to ensure it meets the required level of protection against electrostatic discharge. The standard requires that ESD epoxy flooring should have a minimum electrical resistance of 10⁹ ohms or lower. Additionally, the surface resistivity should not exceed 10¹² ohms when tested according to IEC 61340-4-4.

## Performance Testing for ESD Epoxy Flooring

Performance testing for ESD epoxy flooring is conducted to ensure that the system meets the required standards. The tests are conducted according to IEC 61340-4-4 (Resistivity) and IEC 61340-5-1 (Static Decay).

The Resistivity Test measures the electrical resistance of the ESD epoxy floor system by measuring the voltage drop across the system when a current is applied. The Static Decay Test measures how quickly the system dissipates static electricity when a voltage is applied.

## Maintenance of ESD Epoxy Floor Systems

ESD epoxy floor systems must be regularly maintained in order to maintain their protective properties against electrostatic discharge. The standard recommends that systems should be inspected every 12 months for signs of wear and tear and that any necessary repairs should be carried out immediately. Additionally, it’s important to ensure that the system is regularly tested according to IEC 61340-4-4 (Resistivity) and IEC 61340-5-1 (Static Decay).

## Conclusion

ESD epoxy floor systems are an important part of any high-tech facility. It’s important to understand the different types of ESD epoxy systems available, as well as the applicable standards and performance testing requirements for each type. Additionally, regular maintenance is essential in order to ensure that the system continues to provide adequate protection against electrostatic discharge.