Ppg Epoxy Floor Coating

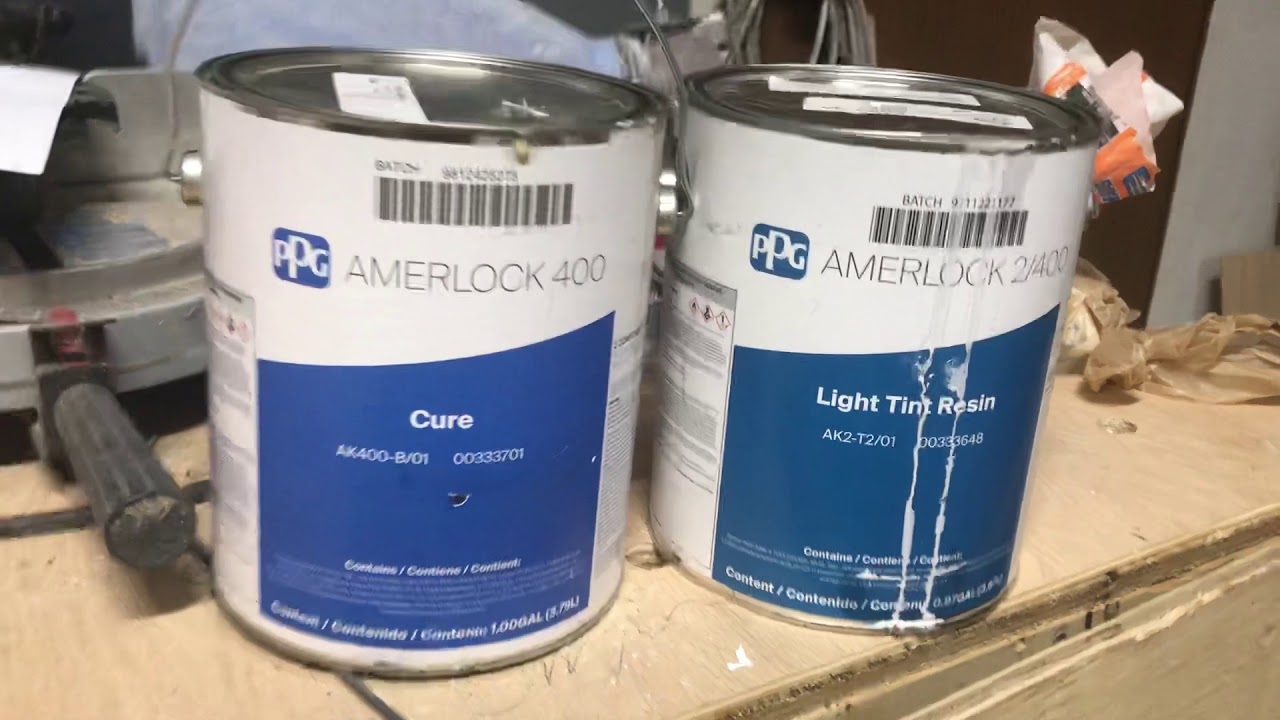

PPG AMERLOCK 400 BLACK 2L PAVING FLOOR FOOD GRADE 2 PACK EPOXY PAINT – Collier Miller

Ppg Garage Floor Coating – Carpet Vidalondon

![]()

Ppg 2 Part Epoxy Floor Paint – Flooring Ideas

Ppg Epoxy Floor Coating – Flooring Guide by Cinvex

PPG AMERLOCK 400 WHITE 10L PAVING FLOOR FOOD GRADE 2 PACK EPOXY PAINT – Collier Miller

Ppg Garage Floor Coating – Carpet Vidalondon

Ppg 2 Part Floor Paint – Carpet Vidalondon

Ppg Garage Floor Epoxy – Flooring Tips

Ppg Garage Floor Coating – Carpet Vidalondon

Ppg Epoxy Floor Coating – Flooring Ideas

PPG Amercoat 385 Epoxy Coating for Metal & Concrete Rawlins Paints

Related Posts:

- Stone Hard Epoxy Flooring

- How To Epoxy Flooring Garage

- How To Repair Epoxy Floor Coating

- Non Slip Epoxy Flooring

- Solid Epoxy Garage Floor

- Quikrete Floor Epoxy

- Paint Flakes Epoxy Floor

- Cheap Epoxy Floor

- Rock Solid Epoxy Floor

- Basement Epoxy Floor Ideas

# PPG Epoxy Floor Coating: A Durable and Attractive Solution for Commercial and Industrial Floors

Are you looking for a durable, attractive, and cost-effective solution for your commercial or industrial flooring needs? Look no further than PPG Epoxy Floor Coating. This high-performance and protective coating system provides long-term protection against wear and tear on all types of floors, while also offering a stylish, modern look.

## What is PPG Epoxy Floor Coating?

PPG Epoxy Floor Coating is a two-component epoxy resin system designed to provide superior performance and protection to all types of floors, including concrete, wood, metal, and more. The system consists of a base coat and a top coat, which are applied in two separate coats in order to provide maximum protection. The base coat is applied first and acts as the bond between the substrate and the top coat. The top coat is then applied as the final layer of protection. The result is an incredibly durable and attractive finish that can withstand heavy foot traffic, extreme temperatures, and harsh chemicals.

## Benefits of PPG Epoxy Floor Coating

PPG Epoxy Floor Coating offers many benefits when compared to traditional flooring materials such as carpet, tile, or linoleum. Not only is it incredibly durable and resistant to wear and tear, but it is also easy to maintain and clean. It also offers excellent resistance to chemical spills, making it perfect for industrial applications. Additionally, epoxy floor coating can be customized with various colors and decorative effects for a unique look that will make any space stand out.

## Installation of PPG Epoxy Floor Coating

Installing PPG Epoxy Floor Coating is relatively simple and can be done by a professional contractor or DIYer. The process begins by preparing the surface for the coating by cleaning it with an appropriate cleaner and removing any debris or contaminants. Once the surface is ready, the base coat is applied in two coats using either a roller or brush. After the base coat has dried completely, the top coat is then applied in two coats in order to protect the floor from wear and tear.

## Maintenance of PPG Epoxy Floor Coating

Once installed, PPG Epoxy Floor Coating requires minimal maintenance in order to keep it looking its best. It should be swept or vacuumed regularly in order to remove dirt and debris that can scratch the surface. It should also be mopped with warm water in order to clean away any spills or stains. In addition, it should be resealed every two years in order to keep its protective properties intact.

PPG Epoxy Floor Coating provides an attractive and durable solution for commercial and industrial flooring needs that will stand up to wear and tear while also offering a unique look. With minimal maintenance requirements and ease of installation, this protective coating system offers an unbeatable value for your money.