Sand Epoxy Floor Coating

Dy-Mark 8L Epoxy Sand Dune Garage Floor Coating Kit Bunnings Warehouse

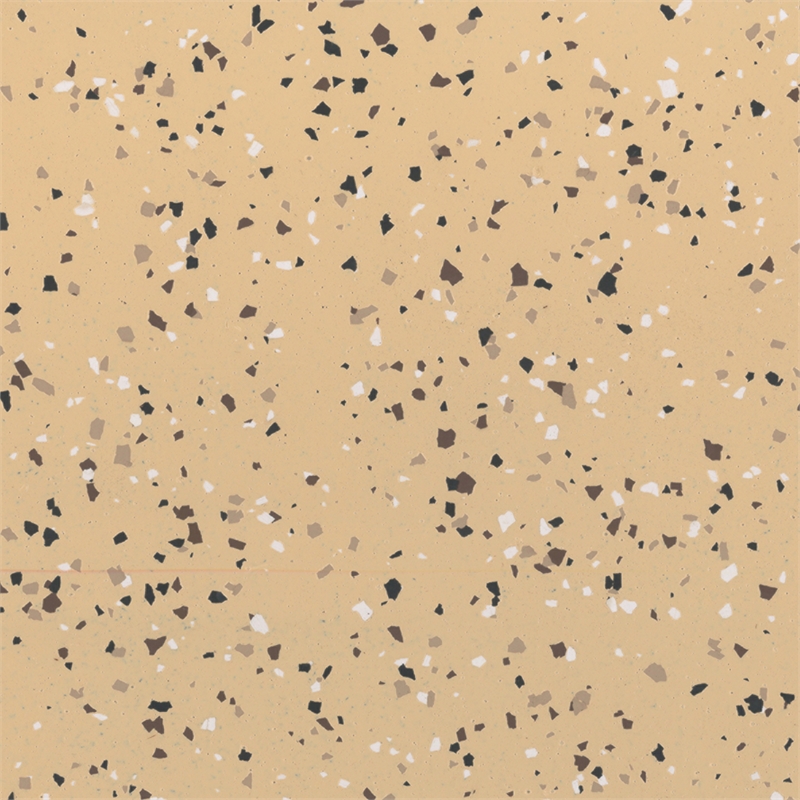

Close Up Of Decorative Quartz Sand Epoxy Coated Floor Or Wall Coating With Grey Black And White

Epoxy Floor Installation Guide Epoxy floor, Floor installation, Sand floor

Extreme Close Up of Decorative Quartz Sand Epoxy Floor or Wall Coating with Light, Pale Green

Epoxy resin colored sand self-leveling floor paint cement concrete coating flooring glue strong

Epoxy Flooring – Perfect CC Midwest Inc.

Epoxy resin colored sand self-leveling floor paint cement concrete coating flooring glue strong

Quartz Sand Epoxy Flooring from $6/sq ft for Sale in Houston, TX – OfferUp

Quartz Sand Epoxy – (864) 314-0027

Commercial entry floor with metallic epoxy. This floor is with Mojave Sand lava flow color

Related Posts:

- Concrete Floor Epoxy Colors

- Clear Epoxy Wood Floor Finish

- Advantages Of Epoxy Flooring

- Crazy Epoxy Floor

- Epoxy Paint Floor Garage

- How To Apply Flakes To Epoxy Floor

- Epoxy Laminate Flooring

- Epoxy Resin Garage Floor Paint

- Designer Epoxy Floor Paint

- Industrial Garage Floor Epoxy

Creating a durable and long-lasting flooring surface is a priority for many homeowners, businesses, and other facilities. Floor coatings are very popular nowadays in the industry. Modern technology has made floor coatings more resilient than ever before. One of the best options for a strong and durable floor is sand epoxy floor coating.

In this guide, you’ll learn all the basics about sand epoxy floor coating, its advantages and disadvantages, color choices, and application process. You’ll find some helpful tips and recommendations to ensure your floor surfaces last for many years to come.

## What is Sand Epoxy Floor Coating?

Sand epoxy floor coating is a two-part system made up of epoxy resin and powder-grade quartz sands. The powder-grade sands give the coating additional strength and resistance while the epoxy resin provides a waterproof seal. This combination of ingredients makes for a stronger, more resilient material that will protect your floors from damage.

When applied correctly, these coatings can last for many years and withstand high traffic. It’s also an excellent choice for various industrial applications because of its durability against stains, oil spills, and chemical fumes.

## Advantages of Sand Epoxy Floor Coatings

The main benefit of sand epoxy floor coatings is its durability and long-term protection. This coating is much more resistant to wear and tear than conventional coatings, so it’s ideal for areas with heavy foot traffic or machinery. It also provides a strong barrier against chemical spills or oil leaks, so it’s a great choice for industrial or commercial facilities.

In addition to its durability, sand epoxy coating provides excellent aesthetic value as well. Its glossy finish gives any surface a professional appearance that will look great for years to come. You can find sand epoxy coatings in multiple colors to match any décor or fit any design scheme.

## Disadvantages of Sand Epoxy Floor Coatings

One of the main downsides to using sand epoxy coatings is its cost. It typically costs more than conventional coatings due to its specialized ingredients and longer application process. In addition, it requires professional installation which will add to the overall cost as well.

Another drawback is that it isn’t as flexible as other floor coatings which can make it difficult to apply in certain areas or with certain materials. Additionally, this type of coating isn’t suitable for outdoor use due to its lack of UV protection and unstable temperatures outside.

## Application Process for Sand Epoxy Coatings

Applying sand epoxy coatings is a multi-step process that should only be done by experienced professionals. The first step involves cleaning the surface area to be coated and removing any dust or debris from the surface. If needed, any cracks or holes should be filled with an appropriate filler before moving on to the next step.

The next step involves mixing the two components of the coating together according to the manufacturer’s instructions and applying it onto the surface using a brush or roller. After this, it’s important to let the coating dry completely before walking on or using the area that was treated. Once the coating has fully dried, you can apply additional coats if desired for increased protection and a longer life span.

## Conclusion

Sand epoxy floor coating is one of the most durable and long-lasting options available on the market today. Not only does it provide superior protection but also provides excellent aesthetic value with its glossy finish and wide range of color options. While there are some drawbacks such as cost and difficulty of application, these are easily offset by its superior performance in areas with heavy foot traffic or machinery exposure. When done correctly, this type of coating can last for many years and provide superior protection to your floors for years to come.

What type of sand is used in sand epoxy floor coating?

The most commonly used sand for sand epoxy floor coating is silica sand. It is economical and readily available. The size of the sand grain is important for achieving the desired texture and finish. Generally, a medium-grade sand is recommended for this type of application.What is the best type of sand for sand epoxy floor coating?

The best type of sand for sand epoxy floor coating is a medium-grit, silica-based sand. Sand with too fine of a grit will not provide enough texture for the epoxy to adhere properly, while a too-coarse grit can cause a bumpy appearance. It is important to use the right size sand grain for the desired outcome.What are the advantages and disadvantages of using sand epoxy floor coating?

Advantages:1. Sand epoxy floor coating provides a long-lasting finish that is resistant to wear and tear, making it a great choice for indoor and outdoor applications.

2. It offers excellent resistance to chemicals, oils, and other substances that may be present in the environment.

3. Sand epoxy floor coating can be applied quickly and easily, making it ideal for DIY projects.

4. The epoxy material is non-porous so it won’t absorb moisture and can be easily cleaned without any hassle.

Disadvantages:

1. Sand epoxy floor coating can be expensive to install.

2. Since it is a two-component material, it must be precisely mixed in order to cure properly.

3. Installation requires the use of protective equipment such as respirators, gloves, and safety glasses.

4. The curing process can take up to 24 hours before the surface is ready to use or walk on safely.

What types of floors are suitable for a sand epoxy floor coating?

Concrete, masonry, wood, and metal surfaces can all be coated with sand epoxy floor coatings. However, the surface must be clean, dry, and free of dust, grease, oil, or other contaminants before it can be coated. It is recommended to first clean the surface with a degreaser and then an acid solution to remove any remaining contaminants.What is the process for applying a sand epoxy floor coating?

1. Prepare the Surface: Make sure the surface is free of dirt, wax, oil, grease, and other contaminants. If necessary, use a degreaser and/or a commercial concrete cleaner to ensure that the floor is properly prepped.2. Grind or Etch: For best results, grind or etch the concrete to create a profile for the coating to adhere to. This will help ensure the longevity of your new floor coating.

3. Vacuum and Tack: Vacuum up any dust created from grinding and then tack (mop) the area with a wet cloth to ensure the dust is removed.

4. Mix Epoxy Sand Coating: Mix together the sand epoxy coating according to manufacturer’s instructions. Make sure you allow enough time for the components of the coating to combine before applying it to the floor.

5. Apply Coating: Apply the mixed epoxy sand coating generously with a trowel and smooth it out evenly. Allow drying time between coats as instructed on product label.

6. Apply Multi-Colored Sand: Once the epoxy has dried, you can apply multi-colored sand for a more decorative finish. Make sure to apply the sand evenly across the entire surface and brush off any excess or uneven bits of sand before it dries.

7. Seal Coating: Once all colors have had a chance to dry, apply one or two coats of epoxy sealer, allowing each coat to dry completely before applying the next one. This will help protect and seal your new floor coating.