Epoxy Flooring Details

Epoxy Flooring Technical Details – Flooring Guide by Cinvex

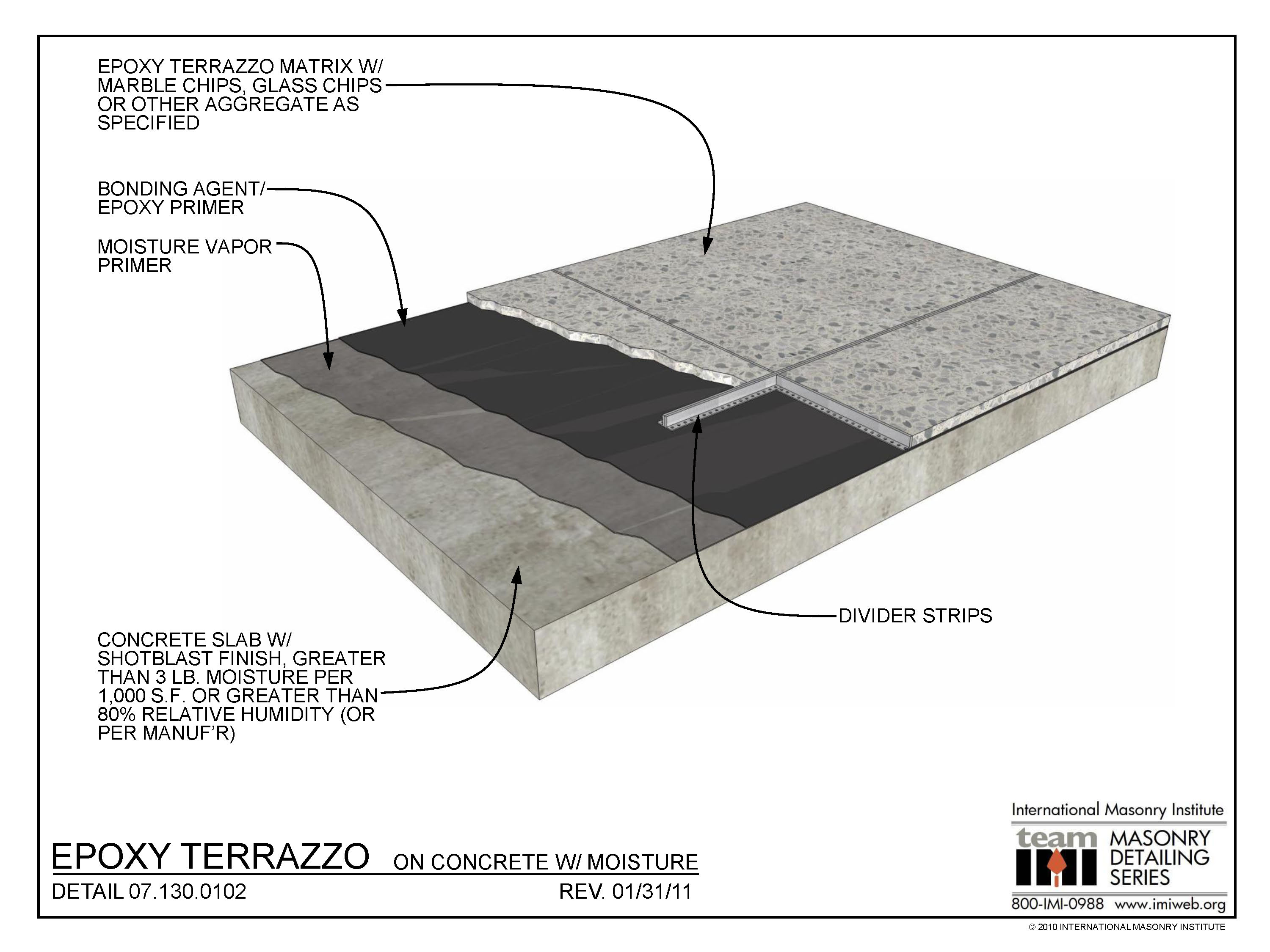

07.130.0104: Epoxy Terrazzo – On Concrete W/ Moisture And Anticipated Cracking International

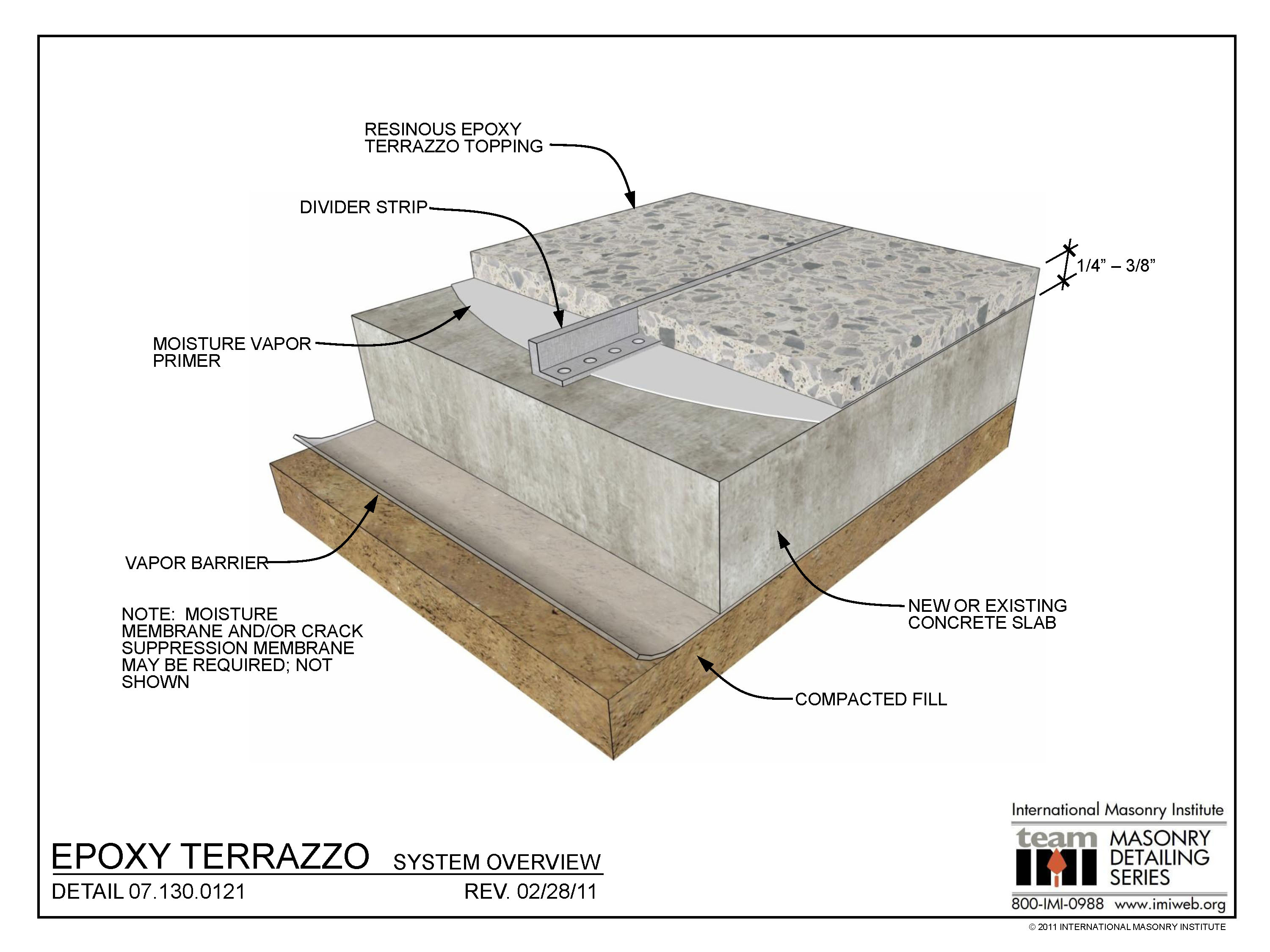

07.130.0121: Epoxy Terrazzo – System Overview International Masonry Institute

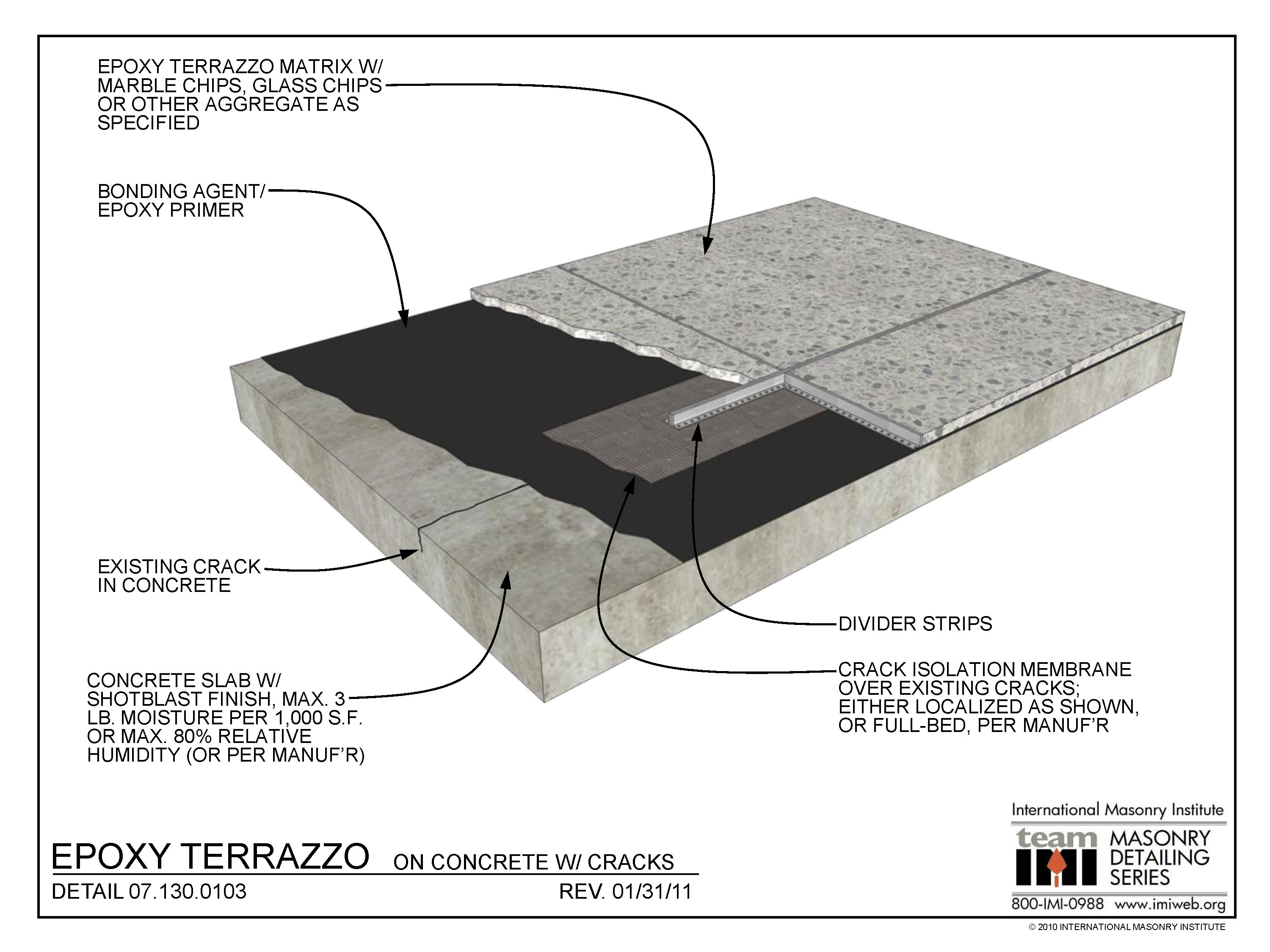

07.130.0103: Epoxy Terrazzo – On Concrete W/ Cracks International Masonry Institute

EPOXY FLOORING SERVICES SECA INDIA EPOXY FLOORING

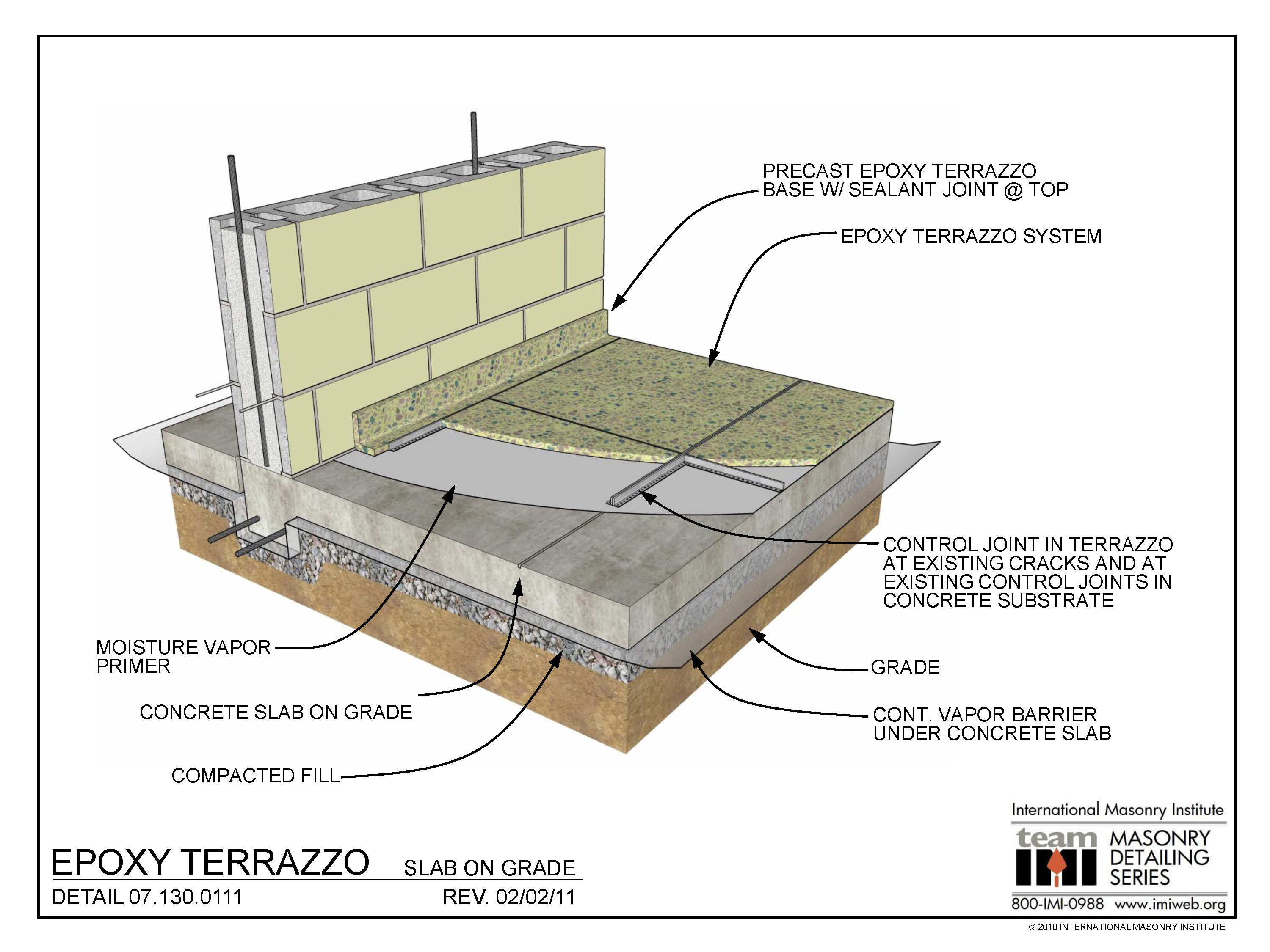

07.130.0111: Epoxy Terrazzo – Slab on Grade International Masonry Institute

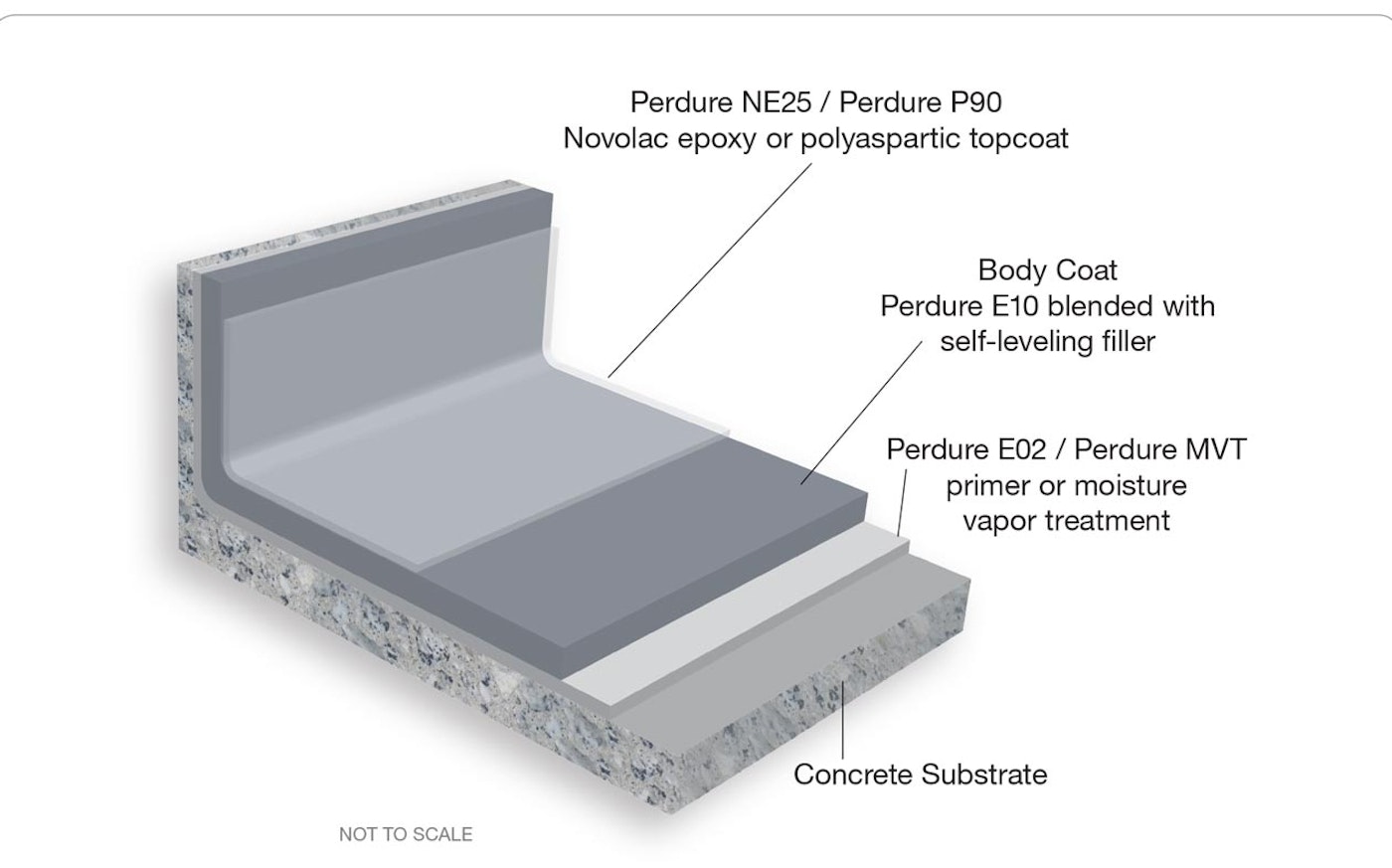

Seamless Self-Leveling Epoxy Flooring over Concrete Substrate

Commercial Epoxy Flooring Solutions in Edmonton RexCoat Flooring

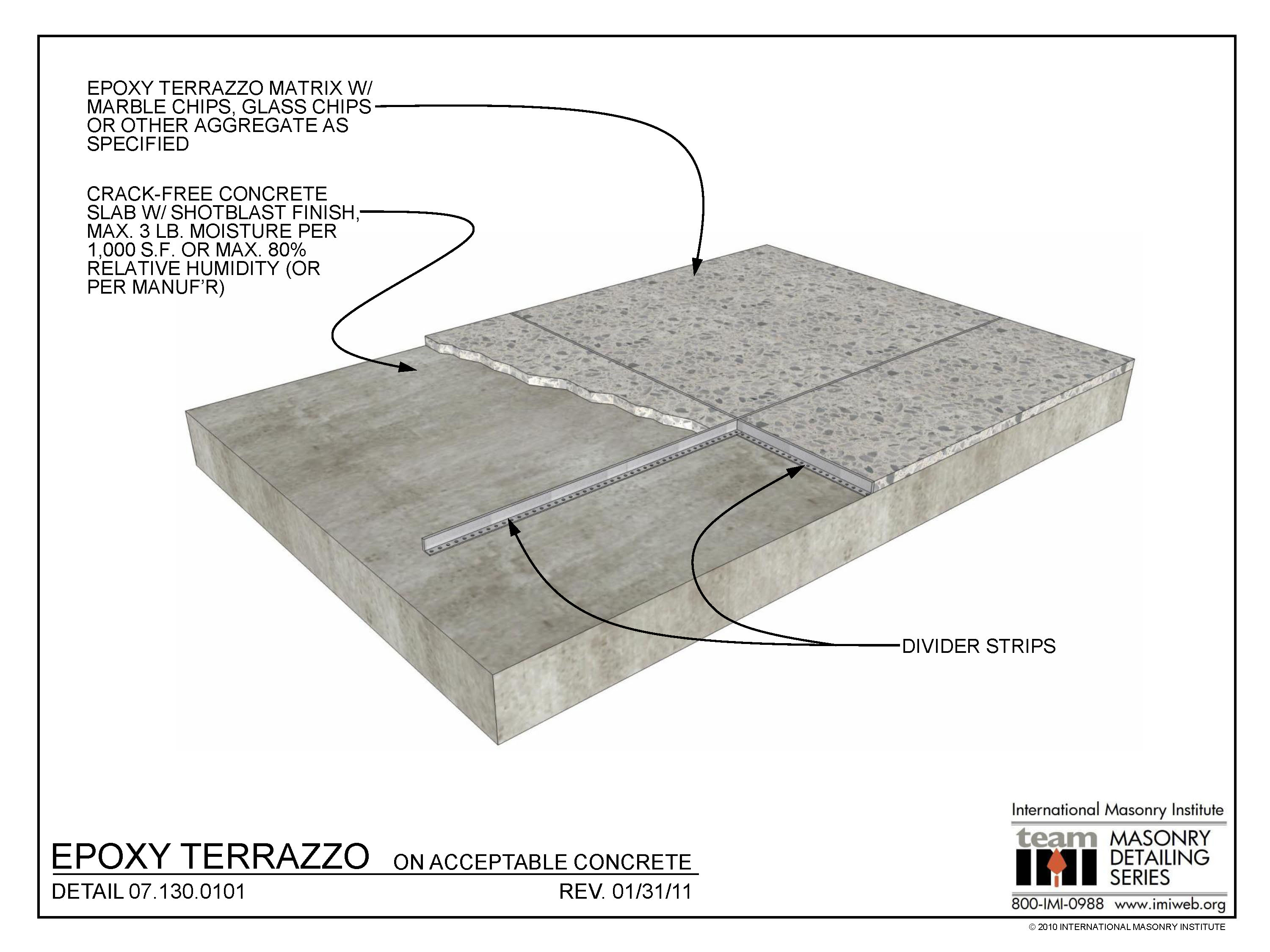

07.130.0101: Epoxy Terrazzo – Acceptable Concrete International Masonry Institute

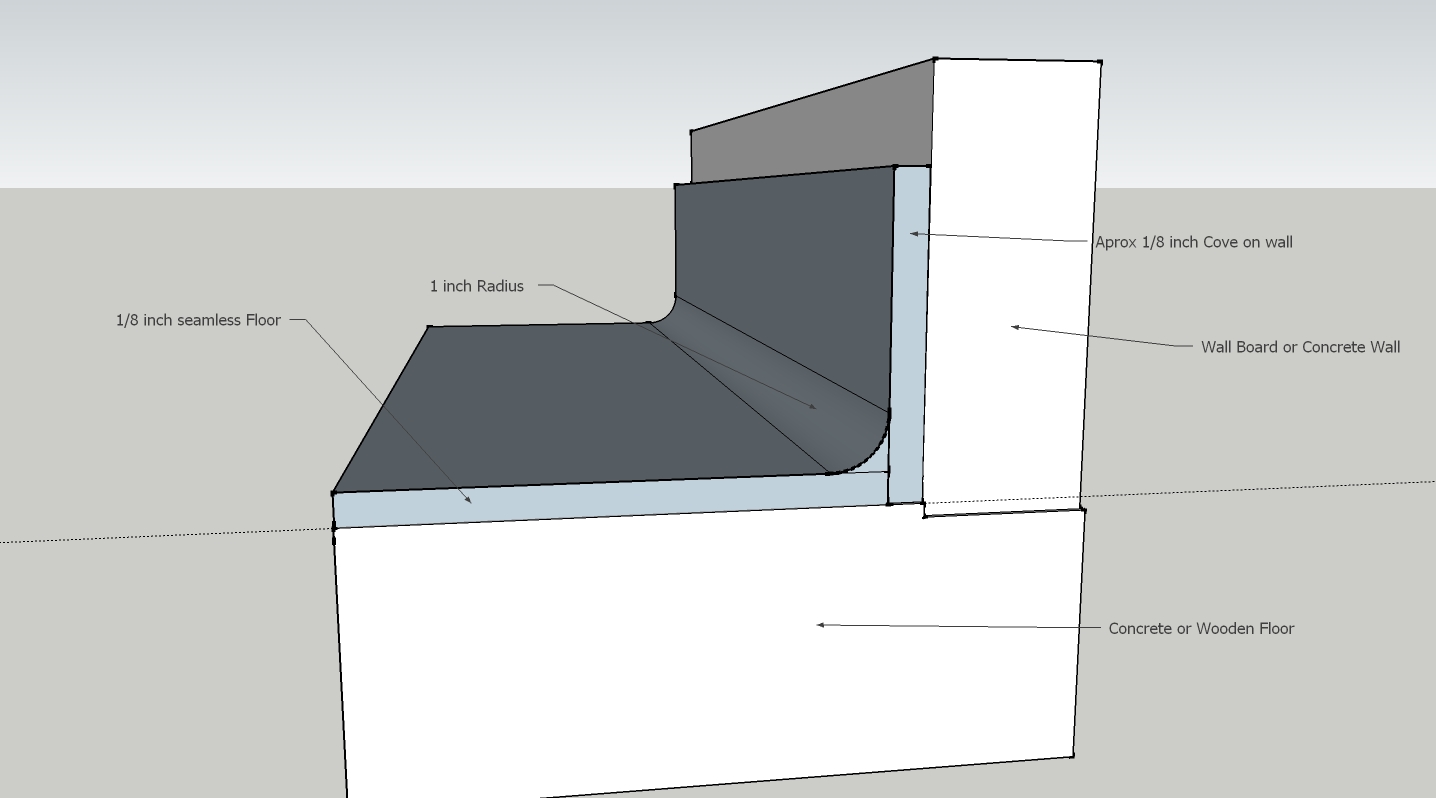

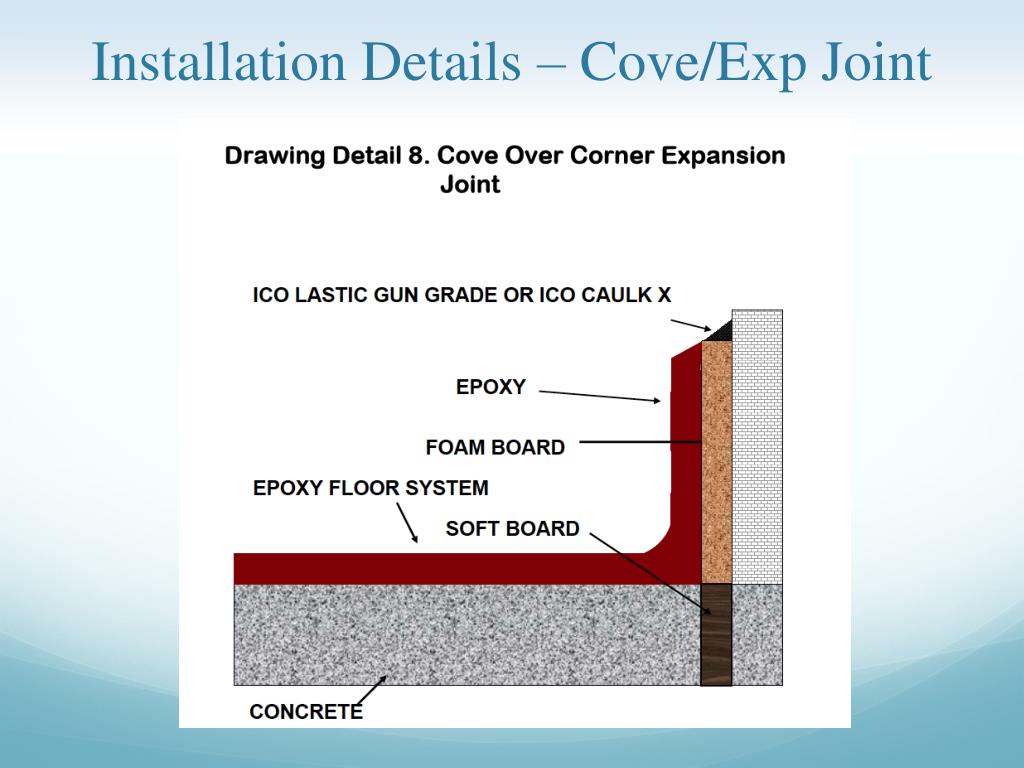

Seamless Epoxy Cove Installation Instructions Epoxy.com News and Tips

Related Posts:

- Fast Cure Epoxy Floor Coating

- Stone Hard Epoxy Flooring

- How To Epoxy Flooring Garage

- How To Repair Epoxy Floor Coating

- Non Slip Epoxy Flooring

- Solid Epoxy Garage Floor

- Quikrete Floor Epoxy

- Paint Flakes Epoxy Floor

- Cheap Epoxy Floor

- Rock Solid Epoxy Floor

Epoxy flooring is a popular flooring option for many businesses and homes. It provides a durable, aesthetically pleasing, and easy-to-clean surface that is also resistant to wear and tear.

Epoxy flooring is a two-part polymer system, consisting of an epoxy resin and a hardener. When these two components are mixed together, they form a strong and durable surface that is both stain and chemical resistant. It can also resist high levels of heat, making it ideal for use in commercial and industrial spaces.

Epoxy flooring is available in many colors and finishes to suit any design style. It can also be used to create unique patterns or designs that will make any space look amazing. Additionally, it is easy to install and maintain, making it a great choice for any home or business owner.

## Benefits of Epoxy Flooring

Epoxy flooring has many benefits, from providing a durable surface that is easy-to-clean to providing a stylish look. Here are just some of the benefits of epoxy flooring:

– Durability: Epoxy flooring is extremely durable and can withstand heavy traffic and wear and tear. This makes it the perfect choice for commercial and industrial spaces as it will last for many years with minimal maintenance required.

– Easy to Clean: Epoxy flooring is easy to clean and maintain, making it ideal for any type of business or home. With regular cleaning, the floor will remain looking fresh and new for years to come.

– Aesthetically Pleasing: The finish of epoxy flooring can be customized to your design style, allowing you to create unique patterns or designs that will make any space look amazing. Additionally, it is available in many colors and finishes, giving you plenty of options to choose from.

– Resistant to Chemicals: Epoxy floors are highly resistant to chemicals such as oils, grease, and other industrial compounds, making them ideal for use in factories or other industrial settings.

## Types of Epoxy Flooring

Epoxy flooring comes in two varieties: solid epoxy floors and broadcast epoxy floors.

Solid epoxy floors are made from a single layer of epoxy resin that is applied directly to the concrete substrate. This type of epoxy flooring is highly durable and resistant to wear and tear. Additionally, solid epoxy floors are very low maintenance as they do not require polishing or buffing like other types of flooring do.

Broadcast epoxy floors are made from multiple layers of epoxy resin that are spread onto the concrete substrate in thin layers. This type of epoxy flooring provides a stronger bond than solid epoxy floors as well as increased durability and resistance to wear and tear. The downside of broadcast epoxy floors is that they require more maintenance than solid epoxy floors due to their multiple layers which require regular polishing or buffing in order to keep them looking new.

## Installing Epoxy Flooring

Installing an epoxy floor requires preparation of the concrete slab before the application of the epoxy system can begin. The concrete substrate must be clean, dry, level, and free from any debris or contaminants that could interfere with the adhesion of the epoxy system. Once the preparation is complete, the application process can begin with the mixing of the two components: the resin and hardener. After mixing these two components together, the mixture should be poured onto the concrete surface where it will then spread evenly across the entire area before being left to cure for 24 hours. After curing, the newly installed epoxy floor should then be allowed to cool before it is ready for use.

## Caring For Your Epoxy Floor

Ensuring your epoxy floor looks its best requires regular cleaning and maintenance. For daily cleaning purposes, simple sweeping or vacuuming can help keep your floor looking fresh and clean while removing any dirt or dust particles that may have accumulated over time. For more stubborn stains or spots on your epoxy floor, you can use a mild soap or detergent with warm water to remove them without damaging your floor’s finish. Additionally, you should avoid using abrasive scrubbers or harsh chemicals when cleaning your floor as these can