Epoxy Garage Floor Coating Kit

DY-Mark 8L Clear Epoxy Garage Floor Coating Kit Bunnings Warehouse

EPOXYSHIELD 1 Car Garage Floor Coating Kit- Gray Gloss – Walmart.com – Walmart.com

Rust-Oleum EPOXYSHIELD Garage Floor Coating Kit – Walmart.com

QUIKRETE 1-Gallon Kit Epoxy Garage Floor Coating Dark Base at Lowes.com

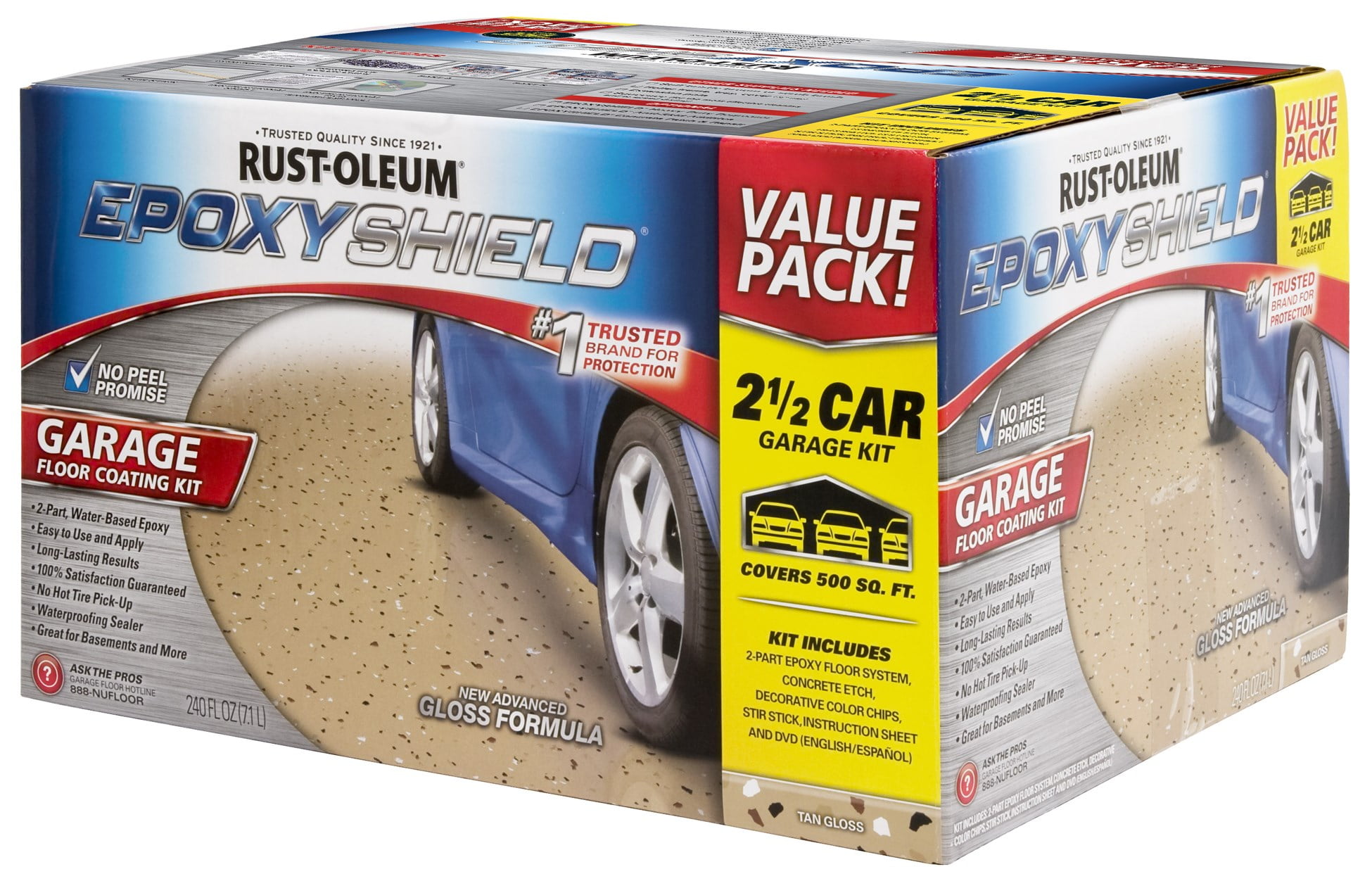

EpoxySheild by Rustoleum 261846 2-1/2 Car Tan Garage Floor Coating Kit – Walmart.com

Rust-Oleum High Performance 2-Part Tan Gloss Garage Floor Epoxy Kit (Actual Net Contents: 128-fl

Rust-Oleum EPOXYSHIELD 2.5 Car Garage Floor Coating Kit, Gray Gloss – Walmart.com – Walmart.com

Car Garage Floor Kit-261842 – The Home

Rust-Oleum EpoxyShield 2 gal. Tan 2-Part High-Gloss Epoxy Garage Floor Coating Kit-251871 – The

Garage Floor Epoxy Kit Canada – Armor Coat Epoxy Garage Floor Coating, Semi-Gloss Grey

Rust-Oleum EpoxyShield 2 gal. Gray 2-Part High-Gloss Epoxy Garage Floor Coating Kit-251870 – The

Related Posts:

- Fast Cure Epoxy Floor Coating

- Stone Hard Epoxy Flooring

- How To Epoxy Flooring Garage

- How To Repair Epoxy Floor Coating

- Non Slip Epoxy Flooring

- Solid Epoxy Garage Floor

- Quikrete Floor Epoxy

- Paint Flakes Epoxy Floor

- Cheap Epoxy Floor

- Rock Solid Epoxy Floor

Are you looking to revamp your garage and give it an attractive, clean look? Look no further than applying an epoxy garage floor coating kit. With the variety of kits available on the market, you can find one tailored to meet your specific needs. Whether you want a professional-looking finish or just a quick DIY job, an epoxy coating is the way to go.

Epoxies provide incredible durability, so you can rest easy knowing that your garage floor will be protected for years to come. They come in a variety of colors, designs, and even textures to match or enhance your existing decor. Applying an epoxy coating is an easy home improvement project that will leave your garage looking brand new.

### Benefits of Applying an Epoxy Garage Floor Coating Kit

Epoxies are an excellent choice for garages due to their numerous advantages. First and foremost, they make cleaning a much simpler task. With other types of coatings, dirt and oil can penetrate the surface, making them difficult to remove with basic cleaning methods. The durable surface of epoxy coatings makes it resistant to spills and stains, making it much easier to keep your garage floor looking spotless.

Also, epoxy coatings are incredibly durable, making them much more resilient than standard paint and sealers. When applied properly, they are resistant to abrasion and cracking or peeling over time. You can receive years and years of use out of your epoxy coating before a reapplication is necessary. Moreover, with epoxies you won’t have to worry about having a slippery floor; they are naturally slip-resistant.

### The Different Types of Epoxy Garage Floor Coating Kits

When choosing an epoxy floor coating kit, be sure to consider the variety of options available on the market. There are two main types of kits: water-based and solvent-based. Water-based kits provide less odor during application, as well as enhanced adhesion and flexibility that solvent-based kits lack. These kits are also not flammable which makes for a much safer installation process. On the other hand, solvent-based kits are known for their superior abrasion resistance, making them ideal for garages where cars are routinely parked or heavy equipment is stored on the floor.

Epoxy coatings also come in a variety of colors and textures that can suit any need or preference. The most popular type is solid color coatings that cover the entire surface with one single color. However, metallic finishes can also give your garage a unique sheen that adds pizzazz to any space. For those who are looking for something more creative, decorative chips can be added during installation in a variety of designs and colors for a custom look that you won’t find anywhere else!

### Preparing Your Garage for Application

Once you have decided which type of epoxy coating is best for you, it’s time to prep your garage for application. Preparation is key when it comes to any type of coating application; if done properly it will ensure that your new coverage lasts as long as possible. The first step is to thoroughly clean the surface in order to ensure that all dirt and debris has been removed prior to application; this will also eliminate any potential contaminants which could spoil the end result. Furthermore, any old paint needs to be sanded down before installing your new epoxy coating in order for it to adhere properly.

Finally, be sure to read through the instructions included with your kit carefully before starting any project; this will save you time and effort in the long run by helping you avoid any potential mistakes along the way! With the right preparation and following directions closely, you can apply an attractive epoxy coating to your garage floor without hassle and enjoy its beauty for years to come!

What are the benefits of epoxy garage floor coating?

1. Durability: Epoxy coatings are extremely durable and can withstand heavy foot traffic, automotive fluids, and even high temperatures.2. Easy to Clean: An epoxy coating can be easily swept and mopped so you won’t have to worry about staining or discoloration from oil spills or other messes.

3. Enhance aesthetics: An epoxy floor coating can give your garage a more polished look and increase the overall value of your property.

4. Slip-resistance: Epoxy coatings provide extra traction and slip resistance so you don’t have to worry about slipping on a wet surface.

5. Chemical/Stain resistance: An epoxy coating is resistant to stains and chemicals, making it easier to keep your garage clean and looking its best.